PROGRESSIVE EPOXY POLYMERS, INC.

Pittsfield NH 03263

Quick EMAIL / ph 603.435.7199 EST / Google SITE SEARCH / Buy On-line TWO STORES / Web Product CATALOGS

** Quick EMAIL / ph 603.435.7199 EST / Google SITE SEARCH / Buy On-line TWO STORES / Goto Contact PAGE / Web Product CATALOG / Progressive Epoxy HOMEPAGE / View our VIDEO / Navigation Bar REPLACEMENT / Data and MSDS PRODUCT INFO / Epoxy Guru HELP SITE / Top Selling Products - FAVORITES * *

We are the only technology based coating/epoxy/resin company that actively encourages your phone calls, not just during our East Coast work hours but also after/before hours, evening, weekends and even holidays. We're available when you are. We form a personal relationship with our customers and freely share technical information, how to-advice, product information and tips-and-tricks. Speak with a non-salesman technical professional with over 25 years of experience in the resin/coating/epoxy industry (no newbie staffer on the phone lines!). Floors, tables, boats, leaks, rot repair. We handle it all! We are an 'always available,' one-on-one, technical/scientific, coating company (watch our video). We are NOT one of those fluffy/slick mass sales firms the dominate the internet selling cheap third party (made in China???), low end epoxies and coatings with no real knowledge of what they are selling and quotas to sell to as many people as possible. 603-435-7199 (east coast time).

ABSOLUTE BEST SOURCE for epoxy information, options, USA made products, 24/7/365 help, and support

(EMAIL 603 435 7199)

|

Read about epoxy web site fibs, half truths, fake facts, and misleading statements before you buy from any online vendor. Knowledge is power! CLICK HERE |

ABSOLUTE BEST SOURCE for epoxy information, options, USA made products, 24/7/365 help, and support

Buy your resins/chemicals from a coatings company, not a marketing firm

Multiple epoxy options - No one single product for everything!"Thanks for all your advice, tips & moral support concerning my project. It turned out beautiful. Quality people backing a quality product is the only way to go!" Joe

Professionals serving Professionals (and informed consumers) - Member: NACE (National Assoc. of Corrosion Engineers) - SSPC (Soc. of Protective Coatings) - BETTER BUSINESS BUREAU (buy with trust)

|

Why You Don't Want, Or Need, A Cycloaliphatic Epoxy Floor Paint |

First things first. New to epoxies? Need to learn the basics of epoxy resins? Here are four articles to get you up to speed.

1) 25POINTS4U.HTML, covers 25 key points about epoxies

2) EPOXYPAINT101.HTML continues the lessons regarding epoxy basics.

3) FAIL4U.HTML explains why coatings can fail

4) EVAL4U.HTML tells you how to evaluate your epoxy and your epoxy vendor

You will find these links on our "Links Page"

Best advice from an Epoxy PRO on how to avoid a $$$ DIY epoxy floor disaster

(you won't learn this on any other epoxy floor site)

If any of the following apply or might apply to you:

1) no vapor barrier, or don't know if there is a vapor barrier under your slab; 2) suspect there might be moisture issues in/on the slab; 3) suspect the concrete was not 'vibrated down' and contains lots of air spaces (which can cause bubbles and blisters in the wet epoxy); 4) cannot professionally prep the floor (usually means a shot blast contractor); 5) any existing coating on the floor is peeling and lifting; 6) the concrete seems dusty, gritty, weak or crumbling; 7) you are worried about "hot tire pickup" lifting off your epoxy floor; 8) you have oil stains on the floor (especially OLD oil stains).......

If so, consider putting an inexpensive epoxy primer / sealer (such as ESP 155 - an Internet Favorite epoxy coating - not for sale in California) on the entire floor or over those potential trouble spots. Then wait a few weeks or months and see what happens. If everything looks great it is very likely that a 'fancy' epoxy top coat will be successful and probably issue free. You might even decide to just keep the sealed floor and skip the thicker mostly decorative (or at least thicker and pigmented) epoxy top coat (such as 0% VOC INDUSTRIAL FLOOR EPOXY).

If problems developed with the thin, nearly clear ESP 155 epoxy sealer, it is not that big a deal. No worse than having some deck/porch enamel paint lift and peel. You won't trip over it, it is not so 'in your face', and you saved big $$$ that you would have spent on the epoxy, paint chip, top coat. Some existing concrete surfaces are just not good candidates for an epoxy coating. QUESTIONS? email OR call 603 435 7199. Floor Links Page. Learn all about epoxy floors.

Floor Coatings Links

Floor epoxy basics -- Floor epoxy web links -- Floor coatings catalog page -- Colored chips site -- Site search -- Contact page

BUY - ESP 155 - Industrial Floor Epoxy - Bio Vee Seal - Acrylic Poly UV Plus - Low V -- VISIT ONLINE STORE SITE - or call 603 435 7199

SELF TEST

Do you know enough about epoxy floor coating products and options to make an intelligent purchase? CLICK HERE to go our 10 POINT TEST, ten questions and issues you should be able to breeze through and answer if you are up to speed on epoxy floor paint options and issues. If you need help, chasing the links to article sites listed here will get you up to speed.

Professional contractors apply our Industrial Floor Epoxy (tm).

Now you can too! catalog page or buy now

|

Cement slab sealers (internal and surface), primers, tie coats help to increase the odds of a successful floor coating project. Read about the two products we recommend CLICK HERE |

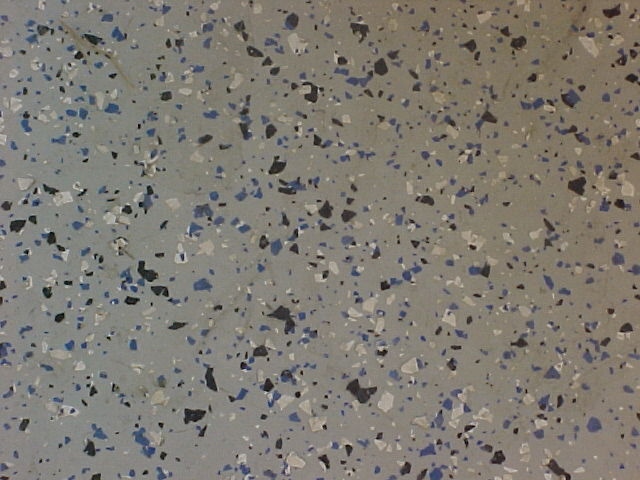

There are three articles the introduce you to epoxy floors. Is your floor suitable for an epoxy coating? There are different kinds of epoxies, which is right for you? Your floor could be a 1 - 7 coat system, figure out what you want. If colored chips in the floor appeals to you, there are lots of other decisions to be made. Chip floors are usually multi coat systems and there are 2 or 3 methods for applying them. They are also usually a blend of epoxy layers and urethane layers. These three articles overlap each other quite a bit, but we'll list them from the most simple article to the more advanced article. BEGINFLOORU4.HTML and FLOORCOATINGS.HTML.

The article about painting your concrete slab gives reason why and problem with applying an epoxy to your concrete/cement slab. Like any of the other articles here, it covers basic information you should know before using any commercial grade epoxy concrete floor coating. SLAB4u.HTML.

Good things seem to come in threes. Yet another set of three articles worth your time dealing with preparing your concrete floor / slab / garage / for epoxy paint. The problem with surface preparation is that you never know if you've done it well enough, or enough of it, until after the fact. In some cases no amount of surface preparation is enough. Coating failure can result from issues outside of your control. Suitable and correct surface preparation is what makes or breaks a professional / commercial epoxy floor contractor. His income and reputation is on the line. He has to call the surface preparation right or he is in big trouble. The good epoxy contractors know when to just walk away from a job rather than bidding on it. Correct surface preparation can make his high fees all worth while. Industrial epoxy surface preparation also has access to 'shot blast' equipment that most homeowners and DIY folks don't have. Article one covers surface preparation in general, not just concrete floors. Article two talks about the options for home owners and article three is strictly about the acid etching method of floor preparation. 1) -- PREP.HTML, 2) -- HOME4U.HTML and finally 3) -- ACID.HTML.

CONCRETE MOISTURE CONTROL.

Water and moisture inside your concrete can keep coatings from sticking as well as producing a dank, musty smell. One product (not an epoxy) that will reduce the the moisture/moisture movement in the concrete is called Bio Vee Seal (tm). Basically if soaks into the exposed concrete then forms crystals in the tiny void spaces. Simply put, it 'clogs up the cement/concrete' thus reducing moisture flow. Read more. VEE4U.HTML

Lots and lots of options here! Grits come in different sizes and have different textures depending upon how thick the coating it is being used with. Also, different kinds of grits, as well as different methods of grit application resulting in different textures. How much grit do you want, 10% coverage or 100% coverage? Also at least two coatings with grit already in them. You could spend an entire winter developing the 'grit' system for your project. Two articles address this topic. GRIT.HTML and NONSLIP.HTML.

An epoxy floor is really just a semi-hard plastic floor. It wears and scratches, especially if running forklifts over it and dragging things across it. The serious commercial epoxy floor involves a rolled down layer of floor epoxy paint completely covered / saturated with sand. Then a sealing topcoat of more epoxy to 'glue down' the top 'layer' of sand. The result is sort of a sand/quartz floor held in place with epoxy rather than just an epoxy painted surface. Commercial / Industrial floor areas use the same pigmented epoxy for the base and topcoat and ordinary hardware store play sand for the sand additive. Fancy applications use blends of color sands and clear coats. The big drawback for this sort colored sand quartz floor is the high shipping costs of the heavy colored sand (need about 1 pound per square foot). QUARTZ4U.HTML

You will not see these kind of articles from most floor epoxy vendors! - Out gassing bubbles, adhesion issues, etc. can be real problems that catch you unexpected. Know what can go wrong by reading these two articles. PROBLEM.HTML and the PINHOLE4U.HTML

About the only place water-based epoxy

paints are used is on floors because they need lots of exposure to air for the

water to evaporate away. These coatings are very user friendly to apply, but the

result is a very thin coating, more like a coat of enamel than epoxy.

(AQUAROCK.HTML)

EPOXY - LATEX - ACRYLIC FLOOR SYSTEM.

With a little imagination you can combine different kind of paint systems for a really unique floor. LATEXFLOOR.HTML

GARAGE EPOXY PAINT - EPOXY GARAGE PAINT.

Painting your garage floor? Issues like tire pick-up, oil, damaged concrete etc. can be real issues. Learn about seamless garage floor epoxy systems with our first article, then read an actual garage floor case study. GARAGE4U.HTML also -- FLOORCS.HTML

|

When it comes to floor epoxies, the way to pick/evaluate your vendor/supplier is not by what they tell you but by what the don't tell you Putting down an epoxy on a cement floor can be tricky and lots of things (some outside of your control) can go wrong, almost all of which have nothing to do with the epoxy (so not the vendors' responsibility). Informing you of possible problems and possible ways around those problems could cost the vendor your business and send you off to a more 'cheerful and happy (and cheaper)' floor epoxy vendor web site. An example is an epoxy primer under the epoxy floor paint. It some situations it could save your butt, but more likely you'll just go to a site that doesn't mention using a primer (thus saving you money and time - but also a flooring failure). What To Watch Out For From Epoxy Floor Vendor Sites: 1) There are water based floor epoxies and solvent free (sometime solvent based) floor epoxies. Some vendors don't explain the differences and use those differences to to make their product sound so much better (when it is an unequal comparison). 2) Epoxies yellow in sunlight (UV) and over time, especially the non-water based epoxies. This should be make know to you up front. 3) If your concrete is weak or crumpling (lots of dusting) - it could be your surface is not a good candidate for an epoxy floor, or at least one without a primer to 'firm' up the surface. Does your vendor mention weak or dusty concrete? 4) Lots of cement floors do not have a vapor barrier under them and those floors may have water - dampness issues (especially in below grade basement situations). Moisture issues under, on, and inside the cement could make an epoxy coating job a potential failure (there are some things you can try). You should be informed of this possible issue. 5) Many cement floors are full of air (cement can be like a sponge) and as the day warms the air in the cement expands and forms bubbles (popped or unpopped) in the starting-to-harden epoxy. The result is a disaster. Where you warned that this could happen? Diid they suggest fixes if your concrete has lots of air? 6) Old oil and grease stains can cause epoxies to peel right off. You may never be able to remove and degrease these areas no matter what you do to clean them. You should know this up-front. 7) Finally, do these vendors rely to emails or phone calls during the evening or on the weekends when you are working on your floor? Shoot them an email on Friday night and see if you get a reply before Monday or ever. |

HOW TO EVALUATE YOUR EPOXY VENDOR -

PAINT VENDOR

|

WATER BASED (WATERBORNE) EPOXY FLOOR PAINTS

|

SOLVENT FREE (or low solvent) EPOXY FLOOR PAINTS |

|

(comparison table) Water Bond Epoxy (tm) med. gray only |

(comparison table) Industrial Floor Epoxy (tm) light gray or beige only |

|

* actually contains voc solvents plus water (restricted in some locations) * slight odor * very long pot life * water clean-up * large coverage per gallon * good color stability * very thin coating - will not hide flaws (may highlight them) * somewhat breathable and some penetration into concrete (good adhesion) * generally less used than solvent free epoxy floor paints * can be primer /sealer under other epoxy (non epoxy) floor systems

|

* no solvents or

VOC issues (solvent free only) * generally odorless * wet thickness equals dry thickness (no shrinking) * thick coating hides flaws and imperfections * can trap air bubbles from expanding air in concrete * shows epoxy yellowing in UV * coverage about 150 sf per gallon * creates vapor seal (radon etc) * can have adhesion issues on damp moisture rich surfaces * tough and durable * standard commercial - professional floor solution * short pot life - working time * use with colored chips or colored sands * works with chips - sands - multi-coat systems |

Note that solvent free floor epoxies only have a working time - pot life of about 15 - 20 minutes at temps from about 55 - 75 degrees (typical temperatures for industrial contractors working inside commercial facilities). For homeowners coating garages in summer (temps in the 80s) pot life could be about 10 minutes. Progressive Epoxy Polymers, Inc., has introduced a 'slow summer' version of our commercial Industrial Floor Epoxy, that returns the 20 minutes or so pot life to our solvent free floor epoxy. No one else offers anything like this (I've searched the internet). Use this product if your application temperature are over about 80 degrees or if you just want a slower pot life (and slower cure).

This page is dedicated to directing you toward internet articles on various aspects of epoxy floor coatings and paints. This includes surface preparation, floors with color chips, things that can go wrong, suitability of the floor for coating, etc.

Unless stated otherwise, CLICK HERE to go to a help page

EPOXY FLOOR LINK PAGE which has the actual

links to the articles described here RE: Epoxy Resin Systems

In the last five years or so there has a massive increase in the number of web sites selling epoxy floor paints to home owners and small businesses. These sites contract sharply with the older traditional sites (including ours) that sell quality epoxies to professional coating contractors and other industry professionals. We suggest you proceed carefully when surfing internet epoxy floor paint sites. The sites are always slick and obviously designed by the marketing department and not the technical staff. They offer prices that range from super cheap to way too high. They tend to be full of promises, pictures and claims, but very weak on actual technical product information about the product itself. The often fail to mention that all epoxies yellow in UV and sunlight, that surface preparation and surface conditions, which are outside the control of the epoxy vendor, can often be a real problem that can make or break a project. Potlife and mixing issues are also downplayed.

|

Brent L. who ordered our solvent free, commercial grade, Industrial Floor Epoxy emailed: "A few weeks ago I ordered epoxy, color chips and UV Poly top coat for my garage (1700 sqf t). You may or may not remember an order of 15 gal of epoxy to Bismarck, North Dakota....

Anyway, I have half the floor done (half because of moving everything in my garage from one side to the other) and the floor looks awesome. People that have seen it are astounded, they've never seen anything like it because no one around here supplies industrial epoxy.

In high school (Calgary, Alberta) I used to work for a company that specialized in epoxy patching of concrete, so I am somewhat familiar with epoxies. I spent many months researching on the Internet what products are available and their cost. The product you have supplied is top notch and I have passed on your name to anyone that is interested."

|

Epoxy Floor On Large Garage - primer/base/chips/clear coat |

|

"Good afternoon Paul! My floor is done and it is all over but the smell from the two part polyurethane top coat. . HA! Cool temps worked in my favor to keep pot-life long but the rainy weather tried to work against me. I ended up tarping over my garage door opening so I could get the area under the seal done without dealing with water on the floor. A cheap rubber squeegee from Harbor Freight was an essential item because it is way too tough to get even distribution of the industrial floor epoxy with just a roller. The squeegee was the same price as a single 24" roller tube anyway and it worked great. I ended up broadcasting chips into the epoxy rather than the clear coat because I wanted a slightly smoother floor. It probably took more chips this way but I think it was a fair trade. If I had to do it over again I'd seriously consider putting chips into a clear epoxy middle coat because even with two coats of poly my basement floor is a bit rougher than I thought it would be. I ended up putting a third coat of UV Poly on the garage floor and it still seems pretty non-skid but is smooth enough that it will be easier to keep clean. The coverage estimates were spot on for Floor epoxy and UV Poly top coat. The Primer was another story, my basement floor was pumped concrete and after bead blasting it was like a cement sponge! The poured concrete on my mail level took the primer as expected. I'm very happy with the results and will be ordering another gallon of UV clear from you when it is time to do the steps and landings. Thanks again!" Gordon 4/16 |

|

About 1600 sf business floor - used Esp 155 primer sealer, 15 gallons of Industrial Floor Epoxy and Acrylic Poly UV Plus two part clear epoxy topcoat. Chips purchased direct from Chipsunlimited.com |

MOISTURE CURED URETHANE EPOXY ALTERNATIVE - ALUMINUM ALUTHANE ------- I received an email on aug. 7th from Sgt. Josh X reminding me how well Aluthane works on floors. "Hello, Have used aluthane before and it is an amazing product. Applied it to a shop floor 6 years ago and no chips or scratches."

|

BANNED FOR LIFE !! Sending people to our FLOOR LINKS site, telling them how to buy decorative paint chips to put into their epoxy direct from the chip manufactures, and suggesting folks email or call me (603-435-7199) AT ANY TIME with their questions about epoxy floors has put me in trouble. I've been banned for life (7/2014) from a popular internet Epoxy Floor forum site. This forum is dominated and run by several epoxy vendors whose purpose is not to help unsuspecting visitors to the site, but rather to sell them product. My private postings to those visitors with honest information and anytime help was seen as a threat to their less than honest methods of generating business. |

|

PARTIAL DATA SHEET |

INDUSTRIAL FLOOR EPOXY (tm) |

|

Warehouse Floors Industrial Floors Restaurant Floors Residential Floors

|

Solvent-Free Good Chemical Resistance Easy 2:1 Mixing Ratio USDA approved for Incidental Food Contact

|

|

STANDARD PRODUCT DESCRIPTION

|

This Industrial Floor epoxy is a 100% solids, USDA acceptable (for incidental contact) epoxy flooring resin designed as a stand alone top coat and as a binder for non-skid surfaces. It is non-blushing and non-water spotting. It bonds to cold, damp surfaces and is high gloss, self leveling and color stable.

|

| USES

|

Roll on top coats Broadcast base and top coats Binder for mortars Supports most industrial traffic Provides an easy non skid surface

|

| FEATURES

|

Good chemical resistance Convenient 2 to 1 ratio by volume Tenacious bond to most substrates USDA acceptable for incidental contact Environmentally safe, solvent free system

|

| VISCOSITY

|

Viscosity at 72°F: Part A: 650 cps Part B: 350 cps Mixed: 500 cps

|

|

PHYSICAL PROPERTIES

|

COMPRESSIVE STRENGTH ........... ASTM D695 12,000 psi

TENSILE STRENGTH ..................... ASTM D638 3,900 psi ELONGATION AT BREAK ............. ASTM D638 7.00%

ABRASION RESISTANCE: CS-17 WHEEL, 1 kg LOAD ............. ASTM D4060 0.10gm loss

WATER ABSORPTION .................. ASTM D570 0/07% (2 hour boil)

FLEXURAL STRENGTH ................. ASTM D790 7,800 psi

SHORE D HARDNESS .................. ASTM D2240 89

HEAT DISTORTION ....................... ASTM D649 122°F TEMPERATURE

BOND STRENGTH TO ................... 100% Concrete failure CONCRETE

APPLICATION RATE ..................... 115 sq. ft./gal (175 sq. ft./gallon and a half kit)

COLORS .......................................... Gray and beige str |

| FIND COMPLETE DATA SHEET AND MSDS - CLICK HERE | |

|

The Benefits of Solvent Free Epoxies (zero VOC - 100% solids) (Same for epoxy paints and epoxy floor paints - see differences between)

* A smooth non-porous, cleanable with strong cleaners surface (thus antimicrobial - mold and mildew resistant) and great for children's play rooms, bathrooms, showers etc.). Thus common in garage, shops, labs, trailers, etc. * Solvent free epoxies little or no odor and no solvents to fill the air (great news for allergy and asthma prone during application) * Wet thickness equals dry thickness (and it is a thick coating to start with) - so equal in thickness to many coats of 'regular' paint. * Thick and self leveling it fills and hides small chips, depressions, cracks etc. Fill them during application and they will not reappear when the epoxy cures.

DISADVANTAGES - all solvent free epoxies yellow, especially in sunlight --- they will scratch --- they have a surface bond only so they needs a top notch bonding surface to adhere to --- there are MOISTURE DURING CURE issues -- solvent free epoxies have a short pot life (working time during application) - air escaping from concrete can form bubbles in the thick solvent free epoxy (there are ways around this, but you need to be told of this possible issue).

CONSUMER WARNINGS - *** Some questionable epoxy vendors like to imply that only their solvent free epoxy has these benefits, which is not true. *** Some questionable epoxy vendors will compare their solvent free epoxy to other vendor's water based epoxies and solvent based epoxies. These are unfair comparisons designed to make their products look 'superior.'*** Some questionable vendors will deny their epoxy yellows (water based epoxies have limited yellowing - dark colors don't show yellowing). *** Some vendors will promote 'special epoxies (novolac, cycloaliphatic, flake filled, coal tar, etc.) when they are not necessary for your intended application. *** Some questionable epoxy vendors will 'forget to mention' the potential disadvantages and problems listed above. *** No epoxy vendor can know the condition and suitability of your surface for an epoxy coating, nor can they oversee your surface preparation, and weather/environmental conditions during your DIY epoxy application. So all vendor Warranty documents have a built in escape mechanism and are presented only as marketing tools to get your business. All that an epoxy vendor can actually warranty is that when mixed correctly the product will harden and have the physical properties described in the product data sheet. An honest epoxy vendor will tell you this up-front.

|

Legal Stuff / Returns

NOTICE: Legal notices, Terms of Service, warranty information, disclaimers, health warnings, etc. are required reading before using web site, ordering and/or using Products. Any such use and/or ordering, online or by telephone, shall constitute acceptance and knowledge of all such terms.

CLICK HERE to access these terms. Please note: Whenever you purchase from this web site, and with each new purchase, you are granting us full and complete permission to add you to our email newsletter list at our option. Accessing this web site, and/or purchasing our products, grants Progressive Epoxy Polymers, Inc. permission to add you to our email newsletter list. You may opt out from the newsletter at any time (link to do so can be found on the newsletter).RETURNS: call or email for authorization to return. Returns are subject to a 25% restock fee. Customer pays return shipping and must comply with federal DOT shipping requirement/labeling for hazmat epoxies under penalty of fines and legal action.

** Quick EMAIL / ph 603.435.7199 EST / Google SITE SEARCH / Buy On-line TWO STORES / Goto Contact PAGE / Web Product CATALOG / Progressive Epoxy HOMEPAGE / View our VIDEO / Navigation Bar REPLACEMENT / Data and MSDS PRODUCT INFO / Epoxy Guru HELP SITE / Top Selling Products - FAVORITES * *

"The Right Epoxy fixes Everything!"

Visit our Subject / Catalog contents PAGE