Layman's Guide to Epoxy Paint / Coating Failures

By Paul Oman

Many maintenance professionals have an uneasy relationship with the coatings (better

know as paint to anyone over 35 years old) they are responsible for maintaining. Recoating (repainting) is at best

an expensive, disruptive nuisance. When coatings fail prematurely the expense and work factors are compounded and

finger pointing runs amuck.

Why do coatings fail? Too many technical articles take the issue down to the molecular

level, providing answers that leave many readers still in the dark. Too often the blame and responsibility is placed

on poorly explained surface preparation which also fails to provide suitable answers. Correct surface preparation

is critical to coating success, but coatings can still fail despite the best preparation.

Below are eight common, useable reasons why coatings fail, as well as possible cures

to these problems and a very Subjective Frequency Rating for each failure type.

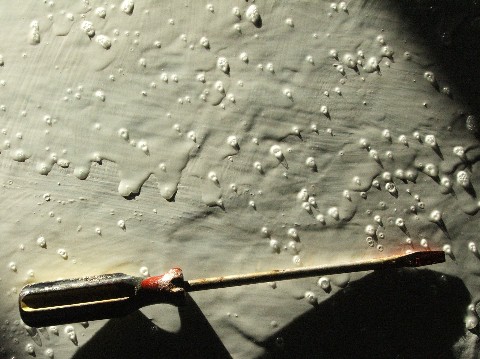

1) WATER/HUMIDITY IMPACT UPON EPOXY

COATINGS

Around concrete surfaces, such as floors, walls and structures, water in the concrete

is a major cause for premature coating failures. We give it our Subjective Frequency Rating of 8 out of 10. Concrete

tends to hold and retain water for a much longer period than most people can or will wait prior to coating. Floors

can have dry areas and damp areas, including some damp areas that never dry out. Touching the surface to test for

dryness can be a misleading method for determining moisture.

High humidity can be as detrimental as moisture. Many coating products do not recommend

applications when humidity exceed 75 or 85 percent. In some places, such as along the Gulf Coast, these humidities

are the daily norms. Many locations can also expect frequent thunderstorms, showers, or rainy periods during certain

times of the year. A little bit of rain every day will keep most concrete structures from every completely drying

out.

Some facilities, like docks, piers, or power plants are either always wet submerged or

else cannot spare the time to permit even marginal dry-out time when recoating is necessary. So what is the solution

to the wet surface problem? There is a new generation of solvent-free epoxy coatings that can actually be applied

underwater. With these coatings the attractive forces between the solid surfaces and the epoxy are greater than

the attractive forces between the surface and the water. The result is the displacement of the water by the epoxy

and a successfully bonded coating underwater.

2) DUST/DIRT IMPACT UPON EPOXY COATINGS

The adhesion of a coating to a surface is only as good as the adhesion of any other coating

separating the two. A layer of dust, dirt, or grease is not going to aid coating adhesion. I have inspected freshly

applied, peeling warehouse floor coatings where the underside of the coating was much dirtier than the top of the

coating. Is there any wonder that the coating failed to bond to the floor?

As new regulations nudge us toward the use of low solvent, low VOC (volatile organic

compounds) coatings, the dust problem becomes more significant. Solvents can sometimes partially dissolve, soak

through or around surface contaminants, or help the coating soak into the substrate. Taking the solvents out of

the coating means those surface contaminants are not going to be mitigated in any way. I give this problem a Subjective

Frequency Rating of 6. The solution is to obtain a clean surface prior to coating.

We really appreciate

you visiting PROGRESSIVE EPOXY POLYMERS, INC. and our web site:

EPOXYPRODUCTS.COM. Take advantage of the CONTACT links on this page to ask

questions about our products and/or your projects. You can stay in touch with us

via our NEWSLETTER (link on our

contact page) which is

emailed every 6-8 weeks.

This

current page is all about:

EPOXY RESIN SYSTEMS

Epoxy paint failures

- Guide to what went wrong

Epoxy Failure - Learn why your paint - coating failed

|

|

WOW!

35%

- 40% of all daily online or telephone orders are from existing

customers. That's an amazing 'REPEAT

CUSTOMER" number. |

|

EPOXY-ONLY WEB SEARCH

|

603 - 435 -

7199 ANYTIME 24/7 FOR HELP OR ORDERS |

|

|

|

3) BREAKDOWN

Sunlight (UV), heat, and chemicals will slowly, or quickly, breakdown any coating. Selecting

the proper coating is obviously the solution, although eventually nature wins anyway. Chemical and UV resistance

varies greatly between coating products, so always check your coating prior to application. I give this a Frequency

Rating of 8.

4) SALTS - IMPACT UPON EPOXY PAINT

ADHESION

It has recently been discovered that corrosion and coating failure often begin on the

underside of the coating, especially on steel surfaces. Sandblasting and grinding can prepare a surface to what

is called white metal' but it cannot remove invisible salt/ion deposits that become corrosion cells' attacking

the metal under the coating. For steel surfaces I give this problem a Frequency Rating of 6. The best solution

appears to be switching from sandblasting to waterjetting (hydro-blasting). The waterjet action can remove all

residual coatings as well as any invisible surface salts.

5) SOLVENTS AND EPOXY PAINTS

As mentioned above, regulations are forcing out the use of solvents (VOCs) in coatings.

While solvents do have many positive advantages, they also have some negative features that help cause coating

failures. Everyone has seen alligator hide' ridges on painted surfaces, especially in places where the coating

is extra thick. These ridges are caused by trapped solvents within the coating. In these thick' areas the surface

of the coating dried too quickly before the underlying coating could release its solvent and dry. The result is

a trapped pocket of undried coating. The ridges are formed because as the solvent leaves the top layer of coating,

that coating shrinks. That is also why when you paint over holes and cracks those voids tend to re-appear as the

solvent-rich coating dries. Solvents can also lift oils out of underlying surfaces, or partially soften what were

well bonded residual coatings, either of which can cause the new topcoat to fail. Do you realize that when you

purchase a coating that is 25% solvent, you are really only getting 3 quarts of coating instead of a full four

quarts? Apply 12 mils of this coating to a surface and when it dries you will only have 9 mils of coating. Will

9 mils be adequate for the job at hand?

There is very little you can do to solve this problem. Solvent free coatings are becoming

the norm. You will be using them! We give this a Frequency Rating of 4.

6) BRITTLENESS OF EPOXY AND EPOXY PAINTS

Many coatings will fail because they cannot handle the expansion/contraction (or movement)

of the underlying surface, or they crack when struck. Brittleness is measured in terms of elongation. Brittle phenolic

epoxies traditionally have elongations of only 2-3 percent. Once a coating cracks, even a tiny micro fracture,

that crack becomes a pathway for moisture and corrosion. It is the beginning of failure for the coating. Look for

coatings that have good elongation. Some products, like the wet surface epoxies mentioned above, are reinforced

with Kelvar (tm) micro-fibers. These fibers act like rip-stop nylon or rebar in concrete. They help keep tiny micro

fractures in the coating from spreading and growing. Brittleness gets a Frequency Rating of 5.

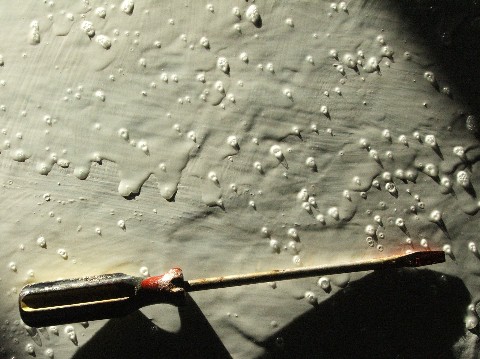

7) PINHOLES IN EPOXY PAINTS - COATINGS

Thin coatings, coatings with good gelling' properties (important for hanging' on vertical

surfaces), and high solvents (which shrink as they dry) can leave behind pinholes' or tiny areas of noncoverage.

Pinholes get a Frequency Rating of 3. The solution to pinholes is multiple coats. Even if one coat will cover,

in critical situations always apply two or more coats, preferably in contrasting colors so that there is visual

confirmation of uniform coverage.

8) POROSITY

Some coatings, including some types of epoxies, are rather porous. They readily absorb

water or chemicals. This can lead to different types of coating failure including blistering. Some coatings add

glass flakes' (mica chips) to physically reduce or slow the flow of water/contaminants through the coating. Many

coatings use other inorganic additives for body and build.' These common additives attract water molecules. Such

coatings are often fine for outdoor use, but not on objects that will be submerged or kept in extremely damp environments.

Here again, the solution is to know your coating. This coating failure gets a Frequency Rating of 2.

SUMMARY

Coatings fail for a number of reasons, the most common being moisture, dirt and contaminants,

and natural breakdown and weathering. Careful selection of your coating, an understanding the possible causes of

failure in your particular situation, and careful surface preparation will all significantly reduce the occurrence

of coating failures.

#####

|