PROGRESSIVE EPOXY POLYMERS, INC.

Pittsfield NH 03263

Quick EMAIL / ph 603.435.7199 EST / Google SITE SEARCH / Buy On-line TWO STORES / Web Product CATALOGS

PROGRESSIVE EPOXY POLYMERS, INC.

Pittsfield NH 03263

Quick EMAIL / ph 603.435.7199 EST / Google SITE SEARCH / Buy On-line TWO STORES / Web Product CATALOGS

** Quick EMAIL / ph 603.435.7199 EST / Google SITE SEARCH / Buy On-line TWO STORES / Goto Contact PAGE / Web Product CATALOG / Progressive Epoxy HOMEPAGE / View our VIDEO / Navigation Bar REPLACEMENT / Data and MSDS PRODUCT INFO / Epoxy Guru HELP SITE / Top Selling Products - FAVORITES * *

Learn about acid etching preparation prior to epoxy floor coating/paint

WHAT THIS SITE COVERS:

What is acid etching?

How do you do acid etching?

Links to epoxy floor web sites and other non acid floor prep options

Acid etching as a surface preparation is the process of applying an acid solution to a concrete surface, allowing

the acid to react with and 'etch' the concrete. This is usually considered a

concrete preparation step prior to the application of an epoxy floor paint

(garage epoxy).

Your Host and Tour Guide:

Paul Oman, MS, MBA - Progressive Epoxy Polymers, Inc. (floor epoxies, marine epoxies, underwater epoxies, repair epoxies)Member: NACE (National Assoc. of Corrosion Engineers), SSPC (Soc. of Protective Coatings)

Board member: Friends of the Suncook River - 501(c)(3) non profit ----- Founder: Friday Night Paddlers .

"Professionals helping Professionals since 1994"

Acid etching as a surface preparation is the process of applying an acid solution to a concrete surface, allowing

the acid to react with and 'etch' the concrete. This is usually considered a

concrete preparation step prior to the application of an epoxy floor paint

(garage epoxy).

Acid etching of concrete is an acceptable, but less popular method for commercial concrete surface preparation than SHOT BLASTING. However, because shot blasting requires special equipment and trained professionals (generally special contractors) acid etching is perhaps the most 'serious' surface preparation method available to 'do it yourselfers'. For such people, as well as professional flooring contractors (if the engineer in charge allows acid etching) the following guidelines are suggested (but not in any way endorsed, recommended or approved - follow at your own risk and responsibility!).

Few DIY folks acid etch due to the possible fumes and the damage that may result to lawns etc. as the used acid is flushed out with water.

Note: check with us regarding a safe, non-hazmat acid etching product that we are considering

stocking.

NOTES SECTION

NOTE: Acid etching of cement floors will not remove sealers or concrete surfaces. They must be removed mechanically - i.e.

shot blasting,

sandblasting, or scarifying. Sealers that soak into the concrete might not be removable at all.

NOTE: Acid etching is often used by individuals for surface preparation of home shops, garages, basements, etc. before the application of an epoxy floor paint.

NOTE: If the concrete is contaminated with oils or grease, the first step is to clean the surface with an alkali detergent cleaner and commercial degreaser (optimal removal is to use the detergent in combination with a steam cleaner).

NOTE

1: HYDROCHLORIC (MURIATIC) ACID

Usually sold in 31% solutions. Dilute to 10%-15%. Use 1 gallon for every 40-50 square feet. A dangerous acid with VERY strong fumes.

2: PHOSPHORIC ACID

Used when the strong acid fumes cannot be tolerated or around acid vulnerable metals such as carbon or galvanized steel. In these situations a solution of 20% - 40% Phosphoric Acid.

3: SULFAMIC ACID

A white powder dissolved in hot water. Much less dangerous to work with than the other acids mentioned above and the best choice for 'do it yourselfers' We sell do not sell Sulfamic Acid (try Home Depot). Mix one pound of Sulfamic Acid with 1 gallon of hot water to treat 300 square feet of concrete.

2) Clean floor with a detergent and rinse well.

3) Make the floor DAMP with ordinary water. Locations where the water beads up on the exposed concrete could be potential problem areas. After completing the surface preparation retest with more water. Do not attempt to coat the area if water still beads up.

4) Apply the acid solution in an even manner using a sprinkling can or acid tolerant pump spray unit.

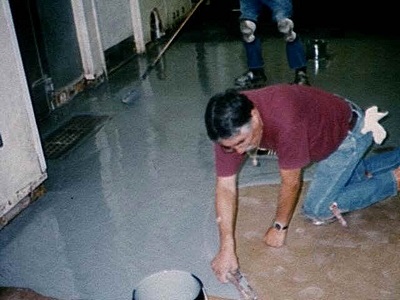

5) Work the acid solution into the concrete with a stiff bristle broom or scrubber.

6) Let the acid sit for 5 - 10 minutes on the concrete.

7) Vacuum or somehow remove the spent acid.

8) BEFORE the acid dries on the surface, remove residue with water hose or other high pressure water sprayer and vacuum up. Simply pouring water on the surface and wet vacuuming will not adequately remove the residue.

9) Neutralize any acid residue. Some people use diluted liquid bleach for this (NOTE: bleach and acids can have a dangerous reaction. It is one thing to neutralize a slightly, well rinsed, acid floor with bleach. It is quite another thing to mix acid and bleach. Don't Do It! - thanks to Scott Edwards for pointing this out!). Follow with lots of rinse water. Others recommend a diluted "Simple Green" cleaner (4 oz per gallon of water). Checking with pH paper is a good idea! A bad acid rinse is probably worse than no acid etching at all.

10) An optional, but potentially very important step is to next wash the surface down with a 'mineral/acid salt remover. Salts on the surface of the concrete do not rinse off easily and can lead to adhesion problems as they absorb moisture becoming corrosive liquids and/or as their crystal structure grows. Although this step is not common, more and more painting contractors are learning about the problem of 'hidden salts' and are starting to use products like our salt remover. If you apply this product, it must be rinsed off well as it dissolves the salts. We sell a 'micro salt' remover wash.

GIVE THOUGHT TO SOLUBLE SALT CONTAMINATION WHICH CAN CAUSE DISBONDING

CLICK HERE FOR MORE INFORMATION on salt contaminationW. A. Hansen HPC, Inc.

The following is a guide to procedures required to properly prepare concrete for the application of thin film coating systems by acid etching.

CAUTION:

Acid etching requires the use of strong chemicals.

Used improperly these chemicals can result in severe injury.

When handling harmful chemicals, always wear protective clothing, protective eyewear / face

shield, rubber gloves, and boots. Do not breath vapors.

Always

add acid to

water. Never add water to acid!

Protect surfaces not to be

etched from chemical vapors, splash and spill.

Dispose of all residual material

according to local and national regulations.

1. Properly clean concrete surface.

2. Properly mix acid solutions.

3. Wet-out concrete surface with fresh / potable water. (No Ponding)

4. Apply acid solution uniformly.

5. Allow acid time to react – 2 – 10 minutes.

6. Rinse / scrub surface.

7. Check profile. Should be between 80 grit – 120 grit open-coat AO sand paper.

8. Check the ph (ideal ph is 7, 6 – 9 is acceptable) Neutralize surface if necessary. Rinse / scrub surface.

9. Dry total surface thoroughly before applying the coating system.

For the best performance from a coating system, concrete must be clean and have a uniform open / porous surface before application. The surface must be etched until this is achieved. More than one etch may be required.

1. Properly clean concrete surface. Remove all dirt, dust, grease, oils, wax, release agents, or any other contaminants that will interfere with the acid etching and preparation of the concrete surface. Mechanical cleaning with brushes by hand or machine will be required for cleaners to work properly. Some contaminants such and sealers and curing compounds may not be removed by cleaning and will require the surface layer of the concrete to be removed by mechanical means. (Shot blasting, sanding, grinding, or any other approved method to remove the contaminant.)

2. Properly mix acid solution. Acids that can be used to etch the concrete are, muriatic, sulfamic, phosphoric, or citric. The most commonly used are muriatic (hydrochloric) and phosphoric acids. Use only plastic or acid resistant containers for mixing and applying acid. Acids concentrations can very. To determine the strength and concentration to use to etch the concrete, test with a very dilute solution then add acid to container until strong bubbling action is noted in the test. Allow approximately 50 – 75 sq. ft. for rough concrete, and 75 – 100 sq. ft. for smooth concrete.

3. Wet-out concrete surface with fresh / potable water. Wet-out the concrete with clean fresh, potable water so the concrete is uniformly wet, without any standing or ponding water. The concrete must stay wet until the acid solution is applied.

4. Apply acid solution uniformly. Apply acid solution uniformly over the surface of the concrete. The use of a plastic watering can will enable you to make sure fresh acid is applied evenly over the surface to be etched. (Do Not take a bucket of acid and dump it over the floor and spread it around with a broom. It will roll over the area and will neutralize as it spreads out giving an uneven etch to the surface of the concrete.) Applied properly to a clean surface the acid will begin to bubble indicating that the acid is reacting with the concrete. (If the acid fails to bubble on all or parts of the floor it means that the surface wasn’t cleaned thoroughly enough and must be cleaned and etched again.) Use a stiff bristle brush to scrub the acid into the surface and remove the layer of concrete to create the profile needed to apply the coating system.

5. Allow acid time to react – 2 – 10 minutes. Allow the acid to remain on the surface of the concrete until the bubbling stops, usually between 2 – 10 minutes. Do not allow any areas of the etched concrete to dry out during this time.

6. Rinse / scrub surface. When the bubbling of the acid on the concrete surface slows noticeably, flush the concrete thoroughly with plenty of water while scrubbing the surface with stiff bristle brooms to remove the powdery residue from the pours of the concrete. This process may need to be repeated more than once to properly rinse the concrete. Collect and dispose of the liquids according to local and national regulations. After the floor is dry any powdery residue that remains on the concrete must be removed before applying the coating system.

7. Check profile. Should be between 80 grit – 120 grit open-coat AO sand paper. Check the profile of the concrete surface. It should be the roughness of 80 grit – 120 grit open-coat AO sand paper. The concrete must have a uniform open / porous surface before application of the coating system. The surface must be etched until this is achieved. More than one etch may be required.

8. Check the pH (ideal pH is 7, 6 – 9 is acceptable) Neutralize surface if necessary. Rinse / scrub surface. After the final rinse check the pH of the wet surface. The ideal pH is 7, (neutral) but a pH of 6 – 9 is acceptable for most coatings unless otherwise specified. If the pH is below 6 residual acid in the concrete surface and must be neutralized. One cup of household ammonia per gal of fresh potable water will usually neutralize the concrete in one application. Apply solution uniformly over the surface. Let stand for 10 minutes before flushing and scrubbing with fresh potable water. Re-check the pH and repeat if pH is below 6.

9. Dry total surface thoroughly before applying the coating system. Check moisture content with acceptable moisture meter. In the absence of acceptable moisture meter follow ASTM Test Method D 4263-83: Standard Test for Indicating Moisture in Concrete by the Plastic Sheet Method. Tape sheets of 4-mil thick polyethylene plastic, at least 18 inch by 18-inch square onto the concrete with 2-inch wide duct tape. Do at least one test for each 500 sq.ft. of concrete. Allow sheets to remain in place for at least 16 hours before removing and testing back of sheet and concrete surface for moisture. Drying the concrete can be accelerated by heat and the use of fans to blow air across the surface to the concrete.

Remember: For the best performance from a coating system, concrete must be clean and have a uniform open / porous surface before application. The surface must be etched until this is achieved. More than one etch may be required.

massive epoxy floor links page (includes links to cement floor prep options)

GOOGLE SITE SPECIFIC SEARCH PAGE -

CLICK HERE (saves a lot of time!)

Legal Stuff

/ Returns

NOTICE: Legal

notices, Terms of Service, warranty information, disclaimers, health

warnings, etc. are required reading before using web site, ordering and/or

using Products. Any such use and/or ordering, online or by telephone, shall

constitute acceptance and knowledge of all such terms.

RETURNS:

call or

email for authorization to return.

Returns

are subject to a 25% restock fee. Customer pays return shipping and must

comply with federal DOT shipping requirement/labeling for hazmat epoxies

under penalty of fines and legal action.

**

Quick

EMAIL / ph 603.435.7199 EST / Google

SITE SEARCH

/ Buy On-line

TWO

STORES / Goto Contact

PAGE / Web Product

CATALOG /

Progressive Epoxy

HOMEPAGE / View

our

VIDEO / Navigation Bar

REPLACEMENT / Data

and MSDS

PRODUCT INFO

/ Epoxy Guru

HELP SITE / Top Selling

Products -

FAVORITES

* *

"The Right Epoxy fixes Everything!"

Visit our Subject / Catalog contents PAGE