PROGRESSIVE EPOXY POLYMERS, INC.

Pittsfield NH 03263

Quick EMAIL / ph 603.435.7199 EST / Google SITE SEARCH / Buy On-line TWO STORES / Web Product CATALOGS

** Quick EMAIL / ph 603.435.7199 EST / Google SITE SEARCH / Buy On-line TWO STORES / Goto Contact PAGE / Web Product CATALOG / Progressive Epoxy HOMEPAGE / View our VIDEO / Navigation Bar REPLACEMENT / Data and MSDS PRODUCT INFO / Epoxy Guru HELP SITE / Top Selling Products - FAVORITES * *

We are the only technology based coating/epoxy/resin company that actively encourages your phone calls, not just during our East Coast work hours but also after/before hours, evening, weekends and even holidays. We're available when you are. We form a personal relationship with our customers and freely share technical information, how to-advice, product information and tips-and-tricks. Speak with a non-salesman technical professional with over 25 years of experience in the resin/coating/epoxy industry (no newbie staffer on the phone lines!). Floors, tables, boats, leaks, rot repair. We handle it all! We are an 'always available,' one-on-one, technical/scientific, coating company (watch our video). We are NOT one of those fluffy/slick mass sales firms the dominate the internet selling cheap third party (made in China???), low end epoxies and coatings with no real knowledge of what they are selling and quotas to sell to as many people as possible. 603-435-7199 (east coast time).

WHAT THIS SITE COVERS:

Are BOX STORE epoxy floor paints any good

?Is my garage suitable for an epoxy floor?

How to apply an epoxy floor

color chips and special effects for epoxy floors

This is Part Two of a two part (garage) floor

paint information page - EPOXY FLOORS PART 1

Garage Epoxy Floor Paint issues

BEST products User guide

Issues you may experience when applying an epoxy floor paint. Best Info on

the web

EPOXY FLOOR PAINT

Professional contractors apply our Industrial Floor Epoxy (tm).

Now you can too! catalog page or buy now

Quick Buy -- INDUSTRIAL FLOOR (tm) EPOXY PAINT - LIGHT GRAY - BEIGE -- Buy Now

massive epoxy floor links page (includes links to DIY cement floor prep options) This is the place to start your epoxy floor education!

Your Host and Tour Guide:

Paul Oman, MS, MBA - Progressive Epoxy Polymers, Inc. (floor epoxies, marine epoxies, underwater epoxies, repair epoxies)

Member: NACE (National Assoc. of Corrosion Engineers), SSPC (Soc. of Protective Coatings)

Board member: Friends of the Suncook River - 501(c)(3) non profit ----- Founder: Friday Night Paddlers .

"Professionals helping Professionals"

"You provide outstanding products, and Fantastic Support. Thank You." Brian S. (call 603 435 7199 anytime)

"Thanks for all your advice, tips & moral support concerning my project. It turned out beautiful. Quality people backing a quality product is the only way to go!" Joe

You will not find our products at any superstore, or being resold (after a 60%-100% markup) by some distributor or agent. Our niche is commercial epoxies made available to homeowners (and professional contractors!) - We offer a range of different epoxy floor coatings and options, including a ready to go kit - DIY Flor-Poxy for those who don't like to make lots of decisions!

Cement slab sealers (internal and surface), primers, tie coats help to increase the odds of a successful floor coating project.

Read about the two products we recommend CLICK HERE

Why You Don't Want, Or Need,

A Cycloaliphatic Epoxy Floor Paint

A water based epoxy system or a thicker solvent free

epoxy floor coating? You'll need to decide this before you can proceed.

"Serious" workshop/industrial/workplace

often use a 2 coat quartz

broadcast epoxy floor floor. "Fancy" residential garages

often like a colored

chip floor system.

USED BY ITSELF, IT WILL REDUCE, OR ELIMINATE, MOISTURE MIGRATION THROUGH CONCRETE FLOORS AND WELLS (THROUGH THE CONCRETE ITSELF, NOT WHEN MIGRATION IS THROUGH CRACKS). IT IS USED ON CONCRETE THAT IS ALWAYS A BIT DAMP AND TO END THE 'MUSTY' OR DAMP SMELL IN BASEMENTS, ETC. PERHAPS MORE IMPORTANTLY, BUT LESS OBVIOUS, IS THAT BY REDUCING OR ELIMINATING MOISTURE MOVEMENT THROUGH THE CONCRETE IT INCREASES THE LIKELIHOOD OF A SUCCESSFUL PAINT OR COATING JOB ON THE CONCRETE SURFACE (NOTE: THIS PRODUCT WORKS BELOW THE SURFACE OF THE CONCRETE, IT LEAVES NOTHING ON THE SURFACE). THIS IS BECAUSE MANY COATING FAILURES ARE THE RESULT OF MOISTURE OR VAPOR PRESSURE BUILDING UP ON THE UNDERSIDE OF COATINGS APPLIED TO CONCRETE.

BECAUSE OF THIS, BIO VEE SEAL IS ALSO A RECOMMENDED, BUT OPTIONAL, PRE-TREATMENT TO CONCRETE SURFACES THAT WILL BE COATED WITH SOME SORT OF SURFACE COATING.

THIS PRODUCT IS LISTED IN OUR CLEAR COATINGS SECTION (SECTION D) CLICK HERE (CLEAR EPOXY) TO GO THERE.

Step 6: sometimes people topcoat the epoxy with a more color stable urethane

(i.e. a snowy white floor) or clear polyurethane (about 20-30 cents per square foot - may need two coats). We now

offer a 2 part urethane clear coat with max UV blockers that should reduce or stop the UV yellowing of epoxies

and maintain a good shine. Not for sale in California. It is called

Acrylic Poly UV Plus.

NOTES: MANY PEOPLE DO JUST ONE OR TWO OF THE PRECEDING STEPS (#2, #3, #4, #5). RARE FOR PEOPLE TO PRE-TREAT (BIO

VEE SEAL), PRIME WITH WATER BASED EPOXY, TOPCOAT WITH SOLVENT FREE EPOXY (PARTIALLY BECAUSE PRODUCTS COME FROM

3 DIFFERENT SOURCES).

IF YOU ARE CONSIDERING CARPETING, WOOD FLOORS, ETC. OVER A CEMENT FLOOR - YOU REALLY DO NEED TO 'SEAL' THE CONCRETE (WE HAVE HEARD LOTS OF HORROR STORIES WHEN PEOPLE DON'T DO THIS). YOU CAN USE ONE OR MORE OF STEPS #2, #3, #4, TO DO THIS.

The colored quartz sands and vinyl chips add a lot of 'snap' to your epoxy floor, but can be an expensive and time consuming project (for more info see links section above). There are easy and cheap alternatives: 1) our ELA link above offers a way to "faux sponge paint" a decorative finish over the epoxy using ordinary latex paint. 2) we have had exciting looking results using "American Accept" stone look spray paint from Walmart and Home Depot over the epoxy and then sealing with a clear coat. 3) really neat and cheap - using cheap spray paint and 'mist' the surface by spraying high and far away. The results are tiny droplets that fall on the dry (day or two old is best) epoxy surface. Using black, white and an deep orange (etc.) will yield a granite like look. If things go bad, immediately wipe the fresh spray paint droplets off with a solvent soaked rag and try again! Practice on a piece of cardboard or construction paper to get the look and colors right before attacking your new epoxy floor. You might want a clear topcoat over the 'spray paint' (our LPU 100 is the best product for this), but we are thinking you probably will not need it. Even if the paint droplets do eventually wear off, you can always reapply......

1) thick, shiny, no solvents or odor - can be slippery when wet; serious commercial stuff - called: INDUSTRIAL FLOOR EPOXY Paint ---

2) water-based floor epoxy - thin - will not hide cracks or flaws but functional and the most user friendly. Sometimes used as a primer under option #1. called: WATER BOND epoxy paint ---

3) solvent based thin epoxy with anti-slip grit - tan color only. Use by itself or over other epoxies. called ROUGH COAT epoxy paint ------

4) high solids ready to go kit - DIY FLOR-POXY (includes chips) epoxy paint

EPOXIES WITH COLORED CHIPS - you pick chip colors and percentages from online color chart. Several different methods to apply - generally a 1 to 4 coat system - you must decide! How much or how little surface prep and primer or no primer - also you decision! We only provide the products - with enough options to get your head spinning.

OPTIONAL PRIMER UNDER YOUR FLOOR EPOXY (GENERALLY A SOLVENT THINNED EPOXY) - USED MAYBE 25% OF THE TIME (RECOMMENDED - ESP 155 EPOXY PRIMER - (NOT FOR SALE IN SOUTHERN CALIF.)

|

Links to Lots of MUST READ Information Articles About the Best Epoxy Floor Paints, Including Preparation, Alternatives, What Can Go Wrong, etc.

|

|

Bio Vee Seal - INTERNAL CONCRETE SEALER |

SOME OF THE SITES THE ABOVE LINK WILL DIRECT YOU TO |

|

Clear Top Coats - FLOOR CLEAR TOP |

Best Floor Epoxy - CLICK HERE |

|

Epoxy Quartz Floor - BROADCAST FLOOR |

Acid Etching - ACID |

|

Epoxy Paint Chip Floor - CHIPS |

Epoxy Paint vs. Floor Epoxy Paint - EPOXY PAINTS |

|

Epoxy Paint - SURFACE PREP |

Floor Basics/Options - START HERE |

|

Floor Epoxy - CATALOG PAGE |

Questions: ASK PROFESSOR E. POXY |

|

ITEMS OFTEN PURCHASED WITH THIS PRODUCT: Industrial Floor Epoxy |

|

* Short nap epoxy

rollers

* ESP 155 epoxy primer * 2 part clear poly with UV blockers (no Calif sales) * Bio Vee Seal internal concrete sealer/moisture control * Film thickness gauge |

| Find in 1-page summary site (marine) with links and prices |

| Find in 1-page summary site (non-marine) with links and prices |

Customer Feedback

Subject: Thanks

Date: Tue, 16 Sep 2003 18:38:01 -0400

From: "Martha & Mark" <xxxxxx@comcast.net>

Hi,

Just wanted to say Thanks for the great product (Industrial Floor Epoxy) and service on my Garage floor project.

It set up great and once I got the nak for Pot Life times, I was off and running laying down the mixture!!

I should have taken before and after photos but it really came out great and most important, I can see the strength

of the Epoxy as a protective

barrier. I look forward to winter now with all it's wrath! This time I'm ready!

Hope to be in touch soon for other projects.

Mark

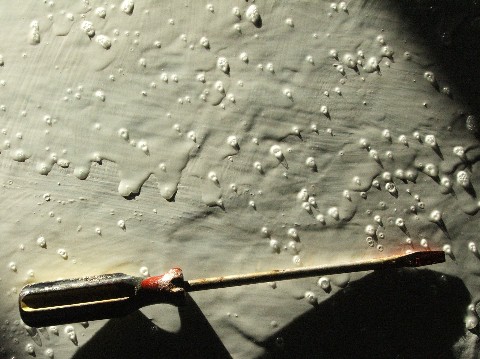

Reasons for coating failures

Manufacturers of Colored Paint chips (buy our chips direct form the manufactures and save $$ - for 100% chip coverage you need about 1 pound per 7 - 10 sf. that said, most 2 car garages like to use about 20 pounds of chips. The low end DIY "garage paint kits" generally only have 1 - 3 pounds of chips per kit. Buy your chips for the source and your epoxy from us!

chipsunlimited.com the nation's primary source for paint chips

Click here - YouTube video. Learn about Progressive Epoxy Polymers Inc.

EVAL4U - how to evaluate your epoxy vendor - CLICK HERE -

|

Let's stay connected. It's a win-win situation. Receive our online NEWSLETTER by emailing us your name and email address. |

| NON STANDARD | FLOOR EPOXIES

|

AND LINKS | ||||

| PENNY FLOORS | basic no blush marine type epoxy | CLICK HERE | ||||

| ============ |

============

|

============

|

||||

| SHIPPING CONTAINER FLOORS | low v clear epoxy | CLICK HERE | ||||

| ============ |

============

|

============

|

||||

| INTERNET FLOOR LINKS SITE | floor links | CLICK HERE | ||||

| ============ |

============

|

============

|

||||

|

"OLD GOAT" FLOOR EPOXY

Q & A |

floor focused help site | CLICK HERE | ||||

| ============ |

============

|

============

|

||||

| FLOOR EPOXY IN ONLINE CATALOG | start shopping here | CLICK HERE |

Legal Stuff / Returns

NOTICE: Legal notices, Terms of Service, warranty information, disclaimers, health warnings, etc. are required reading before using web site, ordering and/or using Products. Any such use and/or ordering, online or by telephone, shall constitute acceptance and knowledge of all such terms.

CLICK HERE to access these terms. Please note: Whenever you purchase from this web site, and with each new purchase, you are granting us full and complete permission to add you to our email newsletter list at our option. Accessing this web site, and/or purchasing our products, grants Progressive Epoxy Polymers, Inc. permission to add you to our email newsletter list. You may opt out from the newsletter at any time (link to do so can be found on the newsletter).

RETURNS: call or email for authorization to return. Returns are subject to a 25% restock fee. Customer pays return shipping and must comply with federal DOT shipping requirement/labeling for hazmat epoxies under penalty of fines and legal action.

** Quick EMAIL / ph 603.435.7199 EST / Google SITE SEARCH / Buy On-line TWO STORES / Goto Contact PAGE / Web Product CATALOG / Progressive Epoxy HOMEPAGE / View our VIDEO / Navigation Bar REPLACEMENT / Data and MSDS PRODUCT INFO / Epoxy Guru HELP SITE / Top Selling Products - FAVORITES * *

"The Right Epoxy fixes Everything!"

Visit our Subject / Catalog contents PAGE

Site sponsor - buy epoxy floor paint web site and domain