THE ANTI SLIP / NON SKID

GRIT ADDITIVE PAGE

Grit products for Anti Slip info - options

Information on various grits and additives for paints and epoxies for anti non slip

Your Host and Tour Guide:

Paul Oman, MS, MBA - Progressive Epoxy Polymers, Inc. (floor epoxies, marine epoxies, underwater epoxies, repair epoxies)

Member: NACE (National Assoc. of Corrosion Engineers), SSPC (Soc. of Protective Coatings)

"Professionals helping Professionals"

PROGRESSIVE EPOXY POLYMERS, INC.

|

PAGE AND SITE NAVIGATION |

|||||||||||||||||

|

Epoxy Floor Links Page ====> This 'Linked To' Sub-Page

No Sales Tax applied. Save Money, you're shopping in Tax Free New Hampshire

MEMBER: Internet Epoxy Confederation (IEC - CLICK HERE TO VISIT) -- "Where Professionalism Still Matters"

We've been selling epoxy - marine epoxy (boat building - wood / fiberglass repair) industrial coatings - garage paint - underwater epoxies - thick putties - tabletop resins and supplies since the early 1990's |

Epoxy Floor Section in our online catalog - CLICK HERE

This was a difficult page to write. I thought about it for over a year. How does one get across the size of various

grits and how they look or feel in a thin coating or in a thick coating? I even purchased a stereo microscope just

so I could evaluate the different grits.

I settled on using ground coffee as the 'baseline' size of 1. Later I took a mm ruler and estimated that my '1' was about 0.66 mm in dia. Here is my best effort at getting this grit info available to you!

GRIT

APPARENT SIZE

ESTIMATED ACTUAL DIAMETER

TEXTURE/FEEL

FIND MARINE CAT

FIND INDUST CAT

extra course walnut (1)

1.75

CLICK HERE

ground coffee (3)

1.0

0.66 mm

med/course walnut (4)

1.0

CLICK HERE

CLICK HERE

Rustoleum grit (5)

0.4

sharp

sugar (6)

0.3

40 grit sandpaper (7)

0.3

sharp

60 grit sandpaper (8)

0.25

sharp

80 grit sandpaper (9)

0.2

sharp

fine walnut (10)

0.2

CLICK HERE

CLICK HERE

150 grit sandpaper (11)

0.1

sharp

our micro sphere filler (13)

0.03

We also sell a very fine white grit for use in solvent based coatings (which shrink down when the solvents evaporate). Called S-15, this grit is the only one that turns clear/invisible in clear coatings. Ideal for a 'fine' texture in varnish, 2 part polyurethanes and other high solvent coatings. Probably way to fine for use with any epoxy except perhaps our solvent thinned ESP 155 sealer. We sell a one pint unit of this product. CLICK HERE (marine or industrial) for more info.

NOTES:

A) we don't sell the ground coffee (#3), the Rustoleum grit (#5), the regular sugar (#6), or the sandpapers. The micro sphere filler is an epoxy thickener included here for comparison. It is not an anti slip grit.

B) under a microscope the walnut shells look like croutons!

2) the rubber grit gives a coarse but soft/rubbery finish like you might expect on a professional diving board.

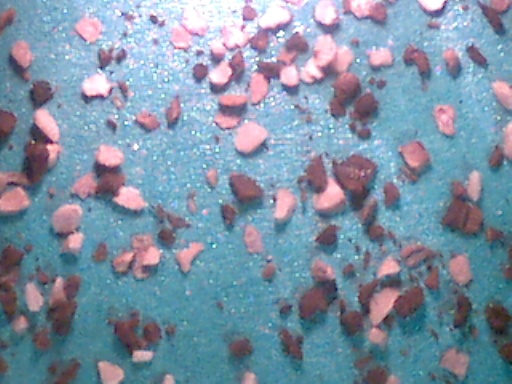

Fine walnut grit - brown grit is ground coffee

medium/coarse walnut grit - brown grit is ground coffee

extra coarse walnut grit - brown grit is ground coffee

We really appreciate you visiting PROGRESSIVE EPOXY POLYMERS, INC. and our web site: EPOXYPRODUCTS.COM. Take advantage of the CONTACT links on this page to ask questions about our products and/or your projects. You can stay in touch with us via our NEWSLETTER (link on our contact page) which is emailed every 6-8 weeks.

This current page is all about:

Grit products for Anti Slip info - options

Information on various grits and additives for paints and epoxies for

anti non slip

|

|

WOW! 35% - 40% of all daily online or telephone orders are from existing customers. That's an amazing 'REPEAT CUSTOMER" number. |

|

603 - 435 - 7199 ANYTIME 24/7 FOR HELP OR ORDERS |

|

|

|

|

Three ways to 'apply'

1) mix the grit into the coating and roll, brush apply. Notes: using a roller gives a more uniform finish than a brush. larger grit is needed for thicker coatings as the finer grits will disappear in the thick coating. The result is an individual grit piece here and there - functional but not too pretty. You can try out your grit by mixing it into some leftover latex paint. This method has problems with very thin, watery coatings. Also, if you are using 'regular' sand don't use this method as the sand may not stay suspended in the paint long enough to get it on the roller.

2) apply the coating and then sprinkle the grit upon the coating and go back over it with the roller/brush. This

is the method when using 'regular' sand. It also works with the other grits. It allows you to decide how much or

how little 'texture' you want. Best use of this system is painting a garage floor (CLICK HERE). If using sugar/salt

as the grit (which you then dissolve away. The resulting voids produce the anti slip texture) you don't back-roll

or brush over.

3)'broadcast to excess' - you completely cover the surface of the coating with enough grit that none of the coating

(or even shiny spots) shows thru. This gives the most uniform, most durable, most attractive results (looks like

sandpaper - to really see/feel the affect brush a thin topcoat of latex paint over the sandpaper). With this method,

after the paint has dried you sweep/blow/vacuum the excess grit away and apply a thin 'sealing' topcoat over the

surface. More info found on our QUARTS BROADCAST PAGE - CLICK HERE.

------------------------

Observations/guidelines

I applied the various grits to our CM 15 epoxy paint, which is a med thick epoxy (similar to floor epoxies or marine

epoxy) both by 'mixing in' and by broadcasting on top. Comments are for both application methods.

The fine walnut felt and looked much like 80 grit sandpaper. Probably best to broadcast upon the coating. I think if mixed into a thicker coating (or if was testing on a rough surface rather than using a tiny brush on a smooth surface) the texture could be lost within the coating (maybe - maybe not).

For folks wanting something a bit rougher (or one that would survive a few layers of 'replacement' paint on top) the med/coarse walnut seemed fine.

The rubber grit and the extra coarse walnut produced a very bumpy/rough surface. Perhaps more than most folks would want on a boat etc. I think in areas where there might be a lot of dirt or oil etc. on the floor (like a garage workshop or food kitchen) and where 'less rough finishes would get buried or overloaded' these produce a suitable thick texture.

I would suggest applying the grits into an epoxy or latex, or enamel base and if top coating, topcoat with thinned epoxy, latex, or enamel.

Epoxy Only Web Google Search

#1) Google

Everything Epoxy Searches

#2) Google

Marine Epoxies Searches

#3)Google

Floor Epoxy Searches View

our Progressive Epoxy Products, Inc.

ON-LINE CATALOG HOMEPAGE.

Inside Our non-marine, commercial, DIY Catalog:

corro coat FC 2100; water gard 300; CM 15; crack coat™; liqua tile 1172 potable water; water prime

Find Corro Coat FC 2100 and Water Gard 300 epoxy in our Best Selling - fix anything Catalog

water bond (water based); industrial floor epoxy; bio vee seal; walnut shell; rough coat grit filled epoxy floor paint; epoxy clear top resi

wet/dry 700; splash zone A-788, epoxy cream; splash zone a-788

Find Wet Dry 700 epoxy in our Best Selling - fix anything Catalog

low V epoxy; basic no blush; ESP 155; Bio-Clear 810; epoxy clear top resin

Find Low V, Basic No Blush, and ES 155 epoxy in our Best Selling - fix anything Catalog

Aluthane moisture cured urethane; Acrylic Poly UV Plus and other 2 part polys ; Capt. Tolley's creeping crack sealer; india spar varnish;

Find Aluthane in our Best Selling - fix anything Catalog

fumed silica; fiber fill; micro balloons/micro-spheres; graphite; wood flour; EZ thick, rock flour;

water activated pipe wrap; TA 661 solvent-free epoxy brush cleaner; fiberglass tape/cloth

short nap epoxy rollers; epoxy/stone deck resurfacing roller; 1 inch foam brushes; 2 inch bristle brushes; tongue depressors

Questions? / Phone order? / EMAIL / CALL 603-435-7199 EST / BUY ONLINE

GOOGLE SITE SEARCH - Click here Epoxy specific site search

Click here - YouTube video. Learn about Progressive Epoxy Polymers Inc.

EVAL4U - how to evaluate your epoxy vendor - CLICK HERE -

|

|

|

||

|

site master |

protagonist |

ground zero |

Grit products for Anti Slip info - options

Information on various grits and additives for paints and epoxies for

anti non slip