epoxyproducts.com

sub-page for BASIC NO BLUSH epoxy resin

Includes key links, customer comments, tables,

pictures, etc for this product

RETURN TO SECTION 1 OF MARINE CATALOG

**

EMAIL //// ph 603.435.7199 EST //// BUY ONLINE (two different online stores) /// RETURN TO MARINE CATALOG HOMEPAGE **More about BASIC NO BLUSH marine epoxy

ASSORTED LINKS

Everyone gets Distributor Pricing for this Top Rated marine epoxy - details .

CLICK HERE TO GOTO OUR USER NOTES SECTION: FEEDBACK FROM MORE FOLKS WHO HAVE USED THIS AND OUR OTHER PRODUCTS.

CLICK HERE FOR DATA SHEET & MSDS

HOW TO EVALUATE MARINE EPOXIES AND MARINE EPOXY VENDORS click here

This product is featured on the GreatThings4u.com website

The least expensive

FORMULATED

marine epoxy available - And

NON BLUSHING

too!

This product has its own web page - CLICK HERE - basic no blush marine epoxy

Visit The Marine Epoxy Everything Guide (click here)

More Basic No Blush user comments and feedback ... CLICK HERE

Additional product information/mentions about BASIC NO BLUSH can also be found at the following site(s) - https://www.paints-coatings-epoxies.com/a_basic_marine_epoxy.html

Additional product information/mentions about BASIC NO BLUSH can also be found at the following MOBILE FRIENDLY site(s) - https://www.everything-epoxy.info/a-marine.html

Basic is a great marine epoxy ("goo") , but if you want a higher quality resin see our Premium No Blush™ marine epoxy below. Basic No Blush™ vs. Premium No Blush™ vs. other epoxies (how to compare) - CLICK HERE

Add some TA 661 - a non solvent epoxy clean up solution to your order! CLICK HERE for more info.

This Product Was Used in The Restoration of the famous Leaf blower Powered Dinghy - CLICK HERE

Using over wood? - read our "primer" page - CLICK HERE

Add solvent to make it a sealer/primer (see www.epoxyproducts.com/penetrating4u.html)

Add thickeners to make it a putty repair epoxy (see www.epoxyproducts.com/repair.html) Use straight for laminating etc.

Allow 36 - 48 hours for enough curing time to provide a strong bond/adhesion to surfaces.

Often also used to reseal epoxy/pebble stone decks (coverage 200-250 square feet per 1.5 gal kit. Also see our special thick roller for this application - Section i Industrial catalog misc. section)

Online log from another boat builder using Basic No Blush - (see - day 42) CLICK HERE

Gluing with Basic No Blush marine epoxy (and other feedback from customers on this product) - see user notes - Basic No Blush™) CLICK HERE

This product reviewed in Professional Boatbuilder Magazine Dec/Jan 2004 CLICK HERE (boat builder)

More customer feedback and comments on Basic No Blush marine epoxy resin- CLICK HERE.

This product has its own web page - CLICK HERE - basic no blush marine epoxy

|

|

BOAT BUILDING SUPPLIES AND INFO |

|

|

Marine Epoxies (find in catalog) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Call 603-435-7199 help/orders |

MISC. INFO

Add Fiberglass tape to your order (3 inch by 50 yards or 4 inch by 50 yards)

see Section 7 - MARINE REPAIR PRODUCTS

|

Epoxy Crazing Notice/Warning |

|

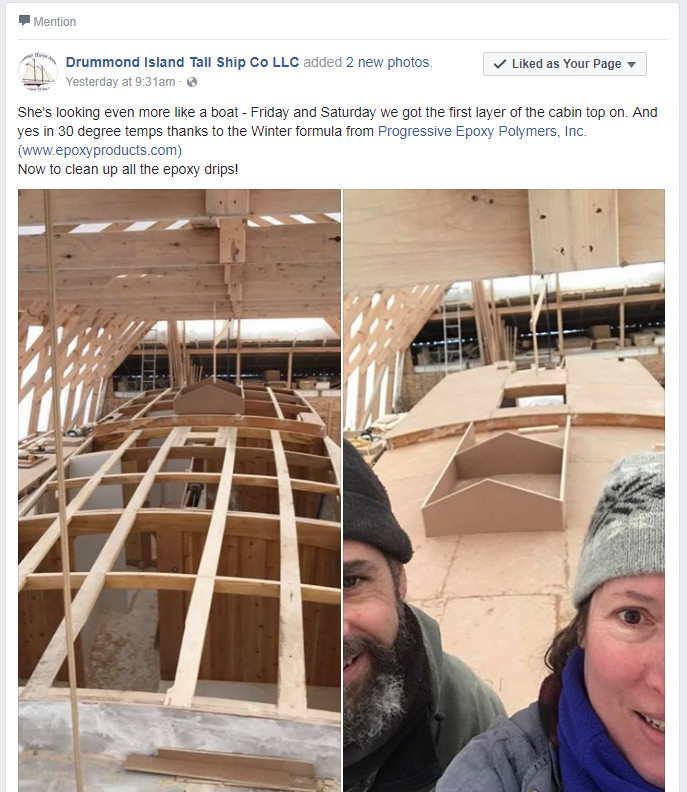

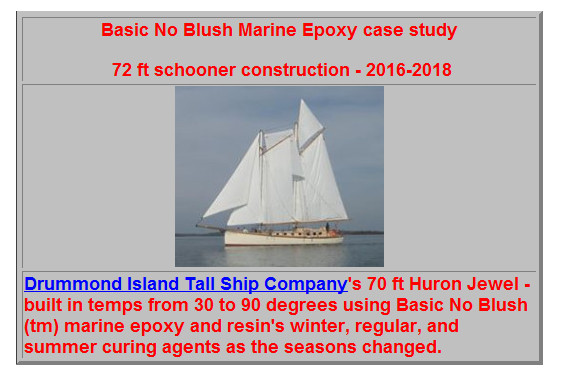

There are two types of Marine Epoxy Vendors: 1) discount, bulk, REPACKAGERS who simple buy drums of raw resin and raw curing agent(s) from the big chemical companies and fill plastic jugs for resale; 2) FORMULATORS take the raw epoxy chemicals add to them to enhance and improve the raw "moonshine" into a "fine whiskey". Learn more repackagers/formulators. Our Basic No Blush (tm) is a formulated non blushing epoxy by Progressive Epoxy Polymers, Inc. (homepage). that includes additions for reduced brittleness and exclusive (only we have it) bubble breakers for a more perfect looking finish. Basic No Blush is the least expensive of the formulated epoxies and considered the best marine epoxy by many ex-users of the other formulated epoxies. REPACKAGED EPOXY WARNING: Over the years I have seen and had reports of non-formulated, raw resin/cure epoxies (which are extremely hard and brittle) becoming crazed with millions of cracks (like shattered safety glass) in outdoor settings that experience big changes in temperature. Formulated epoxies all seem to be 'fixed' to allow for this expansion and contraction without cracking by making them less brittle and better able to handle internal stresses. |

|

Marine Catalog ///// Stitch n Glue ///// Epoxy Only Google Search ///// Epoxy Guru Help Site ///// Marine Boat Epoxy Etc. Links |

| "I've been using the Basic No Blush epoxy on all my own stuff, and using up all the West epoxy on most customers boats. When the West is finally gone I'll only be using your epoxies. Good stuff. I'm rebuilding an old Rybovich so a big order in the future..." Patrick (comment with on-line order 9/4/07) ---- Order No Blush online |

| THIS PRODUCT | xx | EMAIL US | xx | |

| air shippable | cycloaliphatic system | |||

| no nonyl phenol | epoxy adduct system | xx | ||

| multi curing agents | xx | bulk pricing | xx | |

| solvent free | xx | no Calif. sales | ||

| 2 part epoxy | xx | 2 part poly | ||

| apply underwater | bubble breakers | xx | ||

| favorite(s) product list | xx | data sheets | xx | |

| PACKING - jugs/bottles | xx | PACKING - cans | xx | |

| find in non marine cat | xx | find in marine catalog | xx | |

| PRICES/ind/commercial | xx | PRICES/marine section | xx | |

| BUY online | BUY online | xx | ||

| home page | xx | contact page | xx |

|

One of our marine epoxy competitors (now a mere impersonal, product line sub-division within a big industrial corporation) claims a 30% savings in time using non blushing marine epoxies. Non blushing marine epoxies do not require washing or sanding between epoxy coats or top coating with other paints. Note that we offer Basic No Blush marine epoxy with fast, slow and regular curing agents (and it also includes bubble breakers for a more perfect finish). Our Premium No Bush epoxy is Nonyl free and uses an special curing agent is can be air shipped (shipped without restrictions). |

5 oz sample of basic no blush™ marine epoxy resin with regular clear standard curewith epoxy at room temp (73 F) - 25 minutes 64 F - 43 minutes NOTE: our slow summer version is really slow/90 plus degree weather stuff. Even at 85 degrees time to hard could be several hours. 5 oz sample of basic no blush™ marine epoxy resin with thick amber summer/slow curewith epoxy at room temp then approx. 92 degree work environment - 50 minutes with epoxy at work temp of approx. 92 degrees before mixing - 25 minutes with epoxy at room temp (73 F) - 60 minutes

|

|

Basic No Blush Epoxy VS

|

Premium No Blush Epoxy |

| BASIC NO BLUSH™ - our most popular all purpose marine epoxy resin - great value and price! | PREMIUM NO BLUSH™ - non-hazmat for quick AIR shipping and shipping outside the USA - cycloaliphatic curing system Worth considering if you want the Very Best |

| non

blushing very clear easy mix ratio (2 : 1) blendable hardeners --- slow summer, regular and fast winter curing agents nice medium viscosity no VOCs (solvent free) no formaldehyde in the formulationformulated product - not simply repackaged raw resins from the big chemical companies best prices!

|

non blushing easy mix ratio (1.5 : 1) cycloaliphatic curing system nice medium viscosity no VOCs (solvent free) no formaldehyde in the formulation found in some of the popular epoxiesno nonyl phenol in the formulation (98% of epoxies contain Nonyl Phenol) no-nonyl means healthier and no reaction with enamel paintformulated product - not simply repackaged raw resins from the big chemical companies non hazmat to ship! Amber colored curing agent helps bring out the color of natural wood finishes

|

Pumps for 1.5 gal Basic No Blush and Low V epoxy only

approx. 1 oz per stroke - good for small projects after calibration - (most folks use paper cups instead)

APPLICATION EXAMPLES

Our Winter Curing Agent - means 'New England'

winter temps (30's and 40's). If your winter temps

in the 50s generally, order the regular curing agent.

|

Basic No Blush™ marine epoxy resin -in space!It is not just about boats or pebble decks - Basic No Blush epoxy is being used by amateur rocket builder Dr. Dennis McClain-Furmanski PhD LINKS: Light

weight replacement airframe -

https://www.rocketreviews.com/reviews/all/mod_aero_black_diamond.shtml |

|

Custom Drift Boats Check them out at: |

|

|

|

Croff Craft - just one of our commercial boat builders that use our Basic No Blush marine epoxy and India Spar Varnish |

Dory sea trials -

Wind & Oar Boat School - Basic No Blush epoxy customers

https://wind-and-oar-boatschool.org/

|

.

What is a Puddle Duck Racer? (

visit their web site - PDRacer.com) Our BASIC NO BLUSH ™ marine epoxy is the endorsed epoxy within the Puddle Duck community. |

|

BASIC NO BLUSH (tm) MARINE EPOXY - review The only marine epoxy with bubble breakers AND non blushing formulation |

||

|

|

Progressive Epoxy Polymers (epoxyproducts.com) Attn: Paul, Attached is a zip file with photos, plan view, vessel description, and some shots of the previous builds of the same boat. I am using your Basic No-Blush marine epoxy as my sole epoxy coating & glue solution throughout this entire project and I just love your product! Having used all the major brands on the market today I find your epoxy to be the easiest, most consistent, and most forgiving marine epoxy product of them all. This boat is being built in an unheated, semi-weather tight workshop, on an island on Lake Winnipesaukee (central New Hampshire) and consequently I'm more often working in temperatures outside of what is optimal for most epoxies. I've had success with your epoxy (with the Regular curing agent) setting up in temps in the low 50's and also behaving kindly with temps in the upper 80s to 90+. While pot life varies considerably in such a wide range your product is very consistent, predictable, and telling when it's time to 'wrap it up', which is definitely not so much the case with some of your competitors. In addition, your pricing is very attractive and while price is not the primary reason why I use your product I definitely appreciate the value you offer, so thank you. Jeff - 2014 - Offshore Skiff boat builder |

|

|

|

Originally designed for Offshore Magazine, the Offshore Skiff was intended to be an economical shoal-draft family cruiser or alternately--in the open center-console version--an all-around utility boat. A skiff. of course, is any fairly small, shoal, economical vessel. She could be a 15-foot rowboat, a 30-foot Jersey sea skiff, or even a 36-foot 17,000-pound Sea Bright skiff. The Offshore Skiff, falls nicely in the middle of this range at 28-feet 3-inches overall , 24-feet waterline, 8-foot beam. 5400-pound displacement, and drawing a scant 1 1 inches to the bottom of her hull. (She draws 26 inches to the bottom of her outboard.) |

|

|

Massive Boat Links Site |

Buy Now ("marine epoxy" in NAVIGATION BAR) |

BASIC NO BLUSH web page |

USER COMMENTS

Hello Paul:

I have been using basic no blush marine epoxy (standard cure) on my plywood

boat, and I have been impressed. I work on the boat when I have time and

sometimes that means a dry 75-80 degrees, or a hot and humid 95. The epoxy seems

to be very accommodating to temperature and even an accidental improper mixing a

time or two. I am ready to fillet large areas and have been using no blush with

wood flour and have been getting nice looking fillets. I need to place another

order soon...

Larry

"I used 30 gallons of your No Blush epoxy to make a Tolman skiff a few years ago. I am in Japan now, and wondered how much shipping and handling for 1.5 gallons of no blush, std cure costs. Thanks, your epoxy is good stuff. -- best, Ken" (1/17)

The

Wind & Oar Boat School is located

in Portland, OR (https://wind-and-oar-boatschool.org/).

Currently (7/11) they are working on a St Ayles skiff, with a group

of 10 completely novice women doing the build. Its the first all

women build and the first on the west coast. The St Ayles Skiff is a

Iain Oughtred design done for the Scottish Fisheries Museum and now

the cornerstone of the Scottish Coastal Rowing Project (https://scottishcoastalrowing.org/).

Last fall WoodenBoat Publications picked up the concept and got 5

high schools in Maine to start the boat and I am mirroring the idea

for high schools in Portland. The first youth boat will start this

fall but in the mean time a group of women approached me about

building one too. The Wind & Oar Boat School is building communities

through building boats. We encourage groups of all shapes and sizes

to experience the camaraderie, team building, collaboration, and

self confidence that arise from working towards a common goal.

When it came time to decide about epoxies, the school turned to

Michael Bogoger (Dory-man) for advice. He suggested your product and

we've been extremely happy with it. The forgiving nature of the

Basic No-Blush (tm) marine epoxy has been ideal for a school

situation where many people are mixing and consistency is not

necessarily high. Michael has covered our build on his blog several

times and this link

https://dory-man.blogspot.com/2011/06/wind-and-oar-boat-building-school.html)

is to one of his posts where you can see us using the No Blush epoxy

product.

Whether you want a

group team building exercise or a grade school introduction to wood

and water, the Wind & Oar Boat School will tailor a course to fit

your needs. Our first build is a group of 10 women, of diverse ages,

who without any woodworking experience are now building a 22 foot St

Ayles Skiff.

|

"I just wanted to let you know that a couple of months ago I purchased 1.5 gallons of epoxy from you for injection into a port stringer on a waterski boat I recently purchased. I have owned quite a number of boats power and sail requiring repairs to bring them back to where they should be. Your product was excellent in every respect. I thinned it myself to the specifications I felt the repair required and it turned out superb in every regard. I will be using your product in the future for blister repairs to a large sailboat I own and just wanted to thank you for providing an excellent product with value to the consumer." Best Regards, Steve (email 12/16/13 to Progressive Epoxy Polymers, Inc. -- epoxyproducts.com -- attn: Paul Oman) |

Penobscot 17, built by Mike Fields Using Our Basic No Blush Marine Epoxy

To: pauloman@pauloman.com

Hey there,

I finally finished my boat. It is covered one end to other with y'alls epoxy. I really like your Basic No Blush marine epoxy and still no rash!

Mike Fields

(Mike had suffered from Epoxy Sensitivity and skin rashes from other epoxies. We don't know why he had no rash problem with our epoxy, but we're pleased that he didn't!)

“I started building Puffin in January of this year, and launched her in July. I have made a few changes to better meet my needs. Puffin is a joy to sail. She is fast and very forgiving. The pic I'm sending was taken in 25pmh plus wind on Greers Ferry Lake, AR. I plan to sail in the Gulf, and island hop along the Mississippi coast this summer.”

Austin xxxxx @ alum.mit.edu = (5/2013) "Great Product. Have used it many times and recommend it to others often."

HERE AT PROGRESSIVE EPOXY POLYMERS, WE'RE ONE OF OUR BEST CUSTOMERS!

See our annual winter boat projects for the last two years.....

Building the stitch and glue, plywood, "Portuquese Style Dinghy" (winter 2008/2009) - CLICK HERE

Building TOTO (winter 2007/2008) - a plywood Stitch and Glue Kayak - CLICK HERE

RETURN TO SECTION 1 OF MARINE CATALOG

Legal Stuff / Returns

NOTICE: Legal notices, Terms of Service, warranty information, disclaimers, health warnings, etc. are required reading before using web site, ordering and/or using Products. Any such use and/or ordering, online or by telephone, shall constitute acceptance and knowledge of all such terms.

CLICK HERE to access these terms. Please note: Whenever you purchase from this web site, and with each new purchase, you are granting us full and complete permission to add you to our email newsletter list at our option.RETURNS: call or email for authorization to return. Returns are subject to a 25% restock fee. Customer pays return shipping and must comply with federal DOT shipping requirement/labeling for hazmat epoxies under penalty of fines and legal action.

Navigation Bar frame replacement CLICK HERE mobile friendly key site links