WOODEN BOAT RESTORATION REPAIR WITH EPOXY

We are the only technology based coating/epoxy/resin company that actively encourages your phone calls, not just during our East Coast work hours but also after/before hours, evening, weekends and even holidays. We're available when you are. We form a personal relationship with our customers and freely share technical information, how to-advice, product information and tips-and-tricks. Speak with a non-salesman technical professional with over 25 years of experience in the resin/coating/epoxy industry (no newbie staffer on the phone lines!). Floors, tables, boats, leaks, rot repair. We handle it all! We are an 'always available,' one-on-one, technical/scientific, coating company (watch our video). We are NOT one of those fluffy/slick mass sales firms the dominate the internet selling cheap third party (made in China???), low end epoxies and coatings with no real knowledge of what they are selling and quotas to sell to as many people as possible. 603-435-7199 (east coast time).

Epoxy Wooden Boat Repair examples

- Marine Epoxy Putty

Epoxy wood / wooden Boat Hull Repair method using thickened marine epoxy

examples

Your Host and Tour Guide:

Paul Oman, MS, MBA - Progressive Epoxy Polymers, Inc. - (floor epoxies, marine epoxies, underwater epoxies, repair epoxies)

Member: NACE (National Assoc. of Corrosion Engineers), SSPC (Soc. of Protective Coatings)

Board member: Friends of the Suncook River - 501(c)(3) non profit ----- Founder: Friday Night Paddlers .

"Professionals helping Professionals" since 1994

Boat US member since 1980

PROGRESSIVE EPOXY POLYMERS, INC.

|

PAGE AND SITE NAVIGATION |

|||||||||||||||||

Marine Epoxy Links Page ====> Part #3 Sub-Page ====> This 'Linked To'epoxy boat repair Sub-Page

No Sales Tax applied. Save Money, you're shopping in Tax Free New Hampshire

MEMBER: Internet Epoxy Confederation (IEC - CLICK HERE TO VISIT) -- "Where Professionalism Still Matters"

We've been selling epoxy - marine epoxy (boat building - wood / fiberglass repair) industrial coatings - garage paint - underwater epoxies - thick putties - tabletop resins and supplies since the early 1990's |

"The Wet Dry 700 epoxy paste worked great for patching for the rotted dingy transom. I cut out the rot, fitted new oak pieces, and patched with the Wet Dry 700 epoxy. Easy as pie." -- John 1/15 BUY

| Confused? Visit our FAVORITE TOP SELLING PRODUCTS PAGE. Top Products, user comments. Solutions to all your project needs. epoxyproducts.com/favorites4u.html |

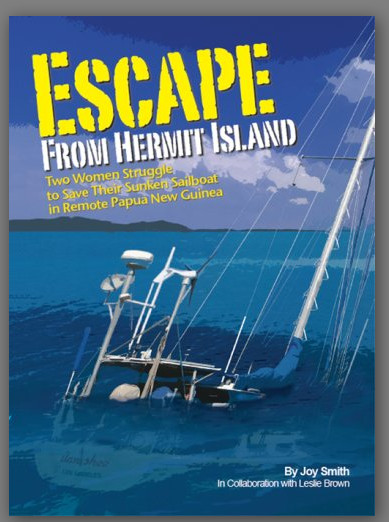

Available at Barnes and Noble and Amazon

EMERGENCY YACHT UNDERWATER REPAIRA Case Study Using Progressive Epoxy Polymer's Underwater Epoxy - WET DRY 700 Underwater Epoxy and Corro Coat FC2100A (BUY NOW) read how our epoxies and customer service saved the day over a decade ago (2003). Read more (click here). Those products and service still available to you - call 603 435 7199 anytime and ask for Paul Oman. Underwater epoxy for Emergency hull repair - sinking yacht Case Study - now in book form at Amazon |

|

Thick Epoxies/paste/gels/putties |

|||

|

|

|

LARGEST SELECTION ANYWHERE CONFUSED? CALL 603 435 7199 talk/order |

|

|

Wet Dry 700 |

STRONG HARD AND TOUGH - APPLY UNDERWATER |

Kevlar (tm) feldspar ceramic reinforced epoxy. About wall mud or cake icing thick. One of our most popular products. Can be applied underwater with or without fiberglass cloth. Has saved leaking boats/pools. Often carried by boats going offshore. Color is off-white but quickly ambers to a golden color. |

Available in quart and gallon units. |

|

Epoxy Cream |

NO PULLING OR DRAGGING SLIDES OFF PUTTY KNIFE SMOOTHLY |

Creamy yellow epoxy used for non structural fairing and filling of holes and voids. Unlike other thick epoxies it slides off a putty knife like a hot knife through butter without pulling or tugging the epoxy behind it. Stays somewhat soft for several days. |

Available in 1.5 quart and 1.5 gallon units. |

|

Crack Coat |

SMOOTH AND FLEXIBLE |

Dark Gray smooth and slick epoxy. About as thick as toothpaste. Uniquely flexible and will bend and move. Use on surfaces that need some "give" due to expansion and contraction, vibration, etc. Good for 'bedding' objects down. Can be applied on damp surfaces. |

Available in three quart units. |

|

Splash Zone A-788 |

ORIGINAL CHEWING GUM LIKE UNDERWATER EPOXY |

The 'Granddaddy' of thick epoxies and underwater epoxies. About chewing gum thick - so thick it needs temps over about 60 degrees to even come out of the can. |

Available in two quart and two gallon units. |

|

"JUST WANTED TO LET YOU KNOW I HAVE COMPLETED MY REBUILD ON THE 1975 SKI NAUTIQUE. I AM MORE THAN IMPRESSED WITH YOUR PRODUCTS AND EVEN MORE SO WITH YOUR CUSTOMER SERVICE. A + COMPANY." - Bob 10/14 |

Basic No Blush epoxy has its own web page - click here (marine epoxy info site).

Buy Wet Dry 700 at our simple alternative site - www.epoxyusa.com

find Wet Dry 700 in our marine

epoxy catalog

find Wet Dry 700 and Basic No Blush marine epoxy in our commercial/residential epoxy catalog

|

Epoxy Crazing Notice/Warning |

|

There are two types of Marine Epoxy Vendors: 1) discount, bulk, REPACKAGERS who simple buy drums of raw resin and raw curing agent(s) from the big chemical companies and fill plastic jugs for resale; 2) FORMULATORS take the raw epoxy chemicals add to them to enhance and improve the raw "moonshine" into a "fine whiskey". Learn more repackagers/formulators. Our Basic No Blush (tm) is a formulated non blushing epoxy by Progressive Epoxy Polymers, Inc. (homepage). that includes additions for reduced brittleness and exclusive (only we have it) bubble breakers for a more perfect looking finish. Basic No Blush is the least expensive of the formulated epoxies and considered the best marine epoxy by many ex-users of the other formulated epoxies. REPACKAGED EPOXY WARNING: Over the years I have seen and had reports of non-formulated, raw resin/cure epoxies (which are extremely hard and brittle) becoming crazed with millions of cracks (like shattered safety glass) in outdoor settings that experience big changes in temperature. Formulated epoxies all seem to be 'fixed' to allow for this expansion and contraction without cracking by making them less brittle and better able to handle internal stresses. |

|

Marine Catalog ///// Stitch n Glue ///// Epoxy Only Google Search ///// Epoxy Guru Help Site ///// Marine Boat Epoxy Etc. Links |

| "I've been using the Basic No Blush epoxy on all my own stuff, and using up all the West epoxy on most customers boats. When the West is finally gone I'll only be using your epoxies. Good stuff. I'm rebuilding an old Rybovich so a big order in the future..." Patrick (comment with on-line order 9/4/07) ---- Order No Blush online |

|

Aluthane (tm) - an MCU sealer/tie coat/color changing sanding base. Use when restoring Wood, Fiberglass, or Metal hulled boats. ALUTHANE. |

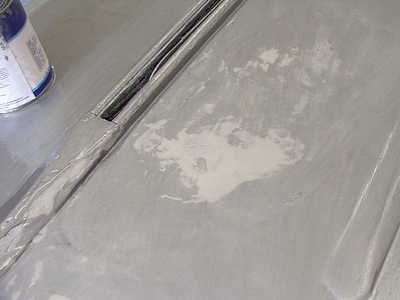

Example 2) Epoxy Fairing the Chipped/Peeled/Damaged Spot

|

Aluthane (tm) - an MCU sealer/tie coat/color changing sanding base. Use when restoring Wood, Fiberglass, or Metal hulled boats. ALUTHANE. |

|

Things go better with Fiberglass Cloth We sell 9 oz fiberglass cloth in 50 yard rolls. Three inch or four inch wide fiberglass "tape". The "tape" is easier for beginners to work with than big sheets of fiberglass - (saturate with epoxy and apply like strips of duct tape). Use for boat-building and/or repair, epoxy pipe wrap projects, and basement leak repair (sort of a dry-wall tape system but using fiberglass cloth and epoxy. Note that when using epoxy and fiberglass cloth, the strength comes from the fiberglass cloth and not the epoxy. - Order the 3 inch or 4 inch fiberglass rolls at either of our on-line stores or call to order your epoxy and cloth - 603 - 435 -7199. |

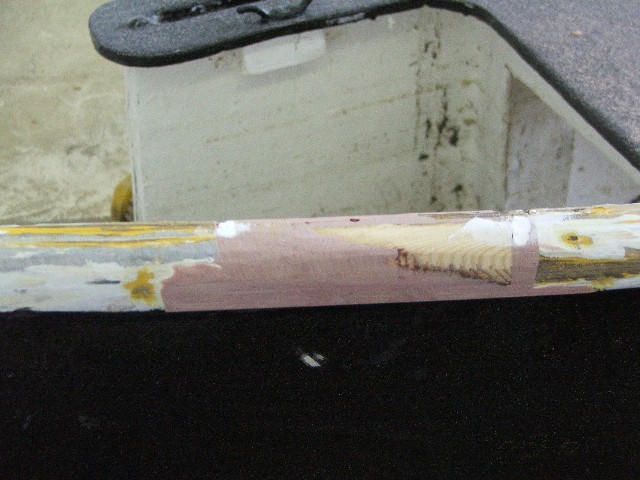

Example 3) Rotten Wood Epoxy Replacement - Sailboat Bowsprit

Rotten Wood Epoxy Repair - Replacement

Sailboat Bowsprit

Using the Wet Dry 700 ™ reinforced two part epoxy paste

1) - view of damaged area

2) all rot removed (important in this case to remove all the rotten wood)

3) - area to be filled - view 1

We really appreciate you visiting PROGRESSIVE EPOXY POLYMERS, INC. and our web site: EPOXYPRODUCTS.COM. Take advantage of the CONTACT links on this page to ask questions about our products and/or your projects. You can stay in touch with us via our NEWSLETTER (link on our contact page) which is emailed every 6-8 weeks.

|

Epoxy Only Web Google Search |

|

|

#1) Google Everything Epoxy Searches #2) Google Marine Epoxies Searches

#3)Google

Floor Epoxy Searches |

|

View our Progressive Epoxy Products, Inc. |

This current page is all about:

Epoxy Wooden Boat Repair examples - Marine Epoxy Putty

Epoxy wood / wooden Boat Hull Repair method using thickened marine epoxy

examples

|

|

WOW! 35% - 40% of all daily online or telephone orders are from existing customers. That's an amazing 'REPEAT CUSTOMER" number. |

|

603 - 435 - 7199 ANYTIME 24/7 FOR HELP OR ORDERS |

|

|

|

|

|

|

BOAT BUILDING SUPPLIES AND INFO |

| Non Blushing Marine Epoxy | Marine Epoxies (find in catalog) |

| Epoxy Fillers / Thickeners | Fiberglass Cloth |

| "Stitch and Glue" building | Underwater Epoxy Repairs |

| Varnish Info | Varnish (find in catalog) |

| Dinghy Repair | Massive Boat Links Site |

| Email Us |

Call 603-435-7199 help/orders |

4) area to be filled - view 2

5) area/void filled with Wet Dry 700 (tm) epoxy

6) hard Wet Dry 700 (tm) epoxy with form removed

7) finished product - repair at other end of spar

Example 4) Marine Railway Underwater Epoxy Repair (8/2011)

The Problem:

Worm/rot damage on the submerged section (13 feet down) of a 300 ton marine railway in New York. Railway is reported

to be 100 years old.

The Epoxy Repair:

over 20 gallons of Wet Dry 700 (tm) epoxy mixed with sand and/or small gravel stones applied by divers into the

damaged removed voids in the wood.

VISIT OUR PAGE ON UNDERWATER EPOXIES WWW.EPOXYPRODUCTS.COM/UNDER4U.HTML

Buy Wet Dry 700 (tm) epoxy at our simple alternative site - www.epoxyusa.com - basic no blush marine epoxy

find Wet Dry 700 in our marine

catalog (wet dry 700 underwater epoxy repair paste)

find Wet Dry 700 in our commercial/residential catalog

####

|

Before boat is sad shape |

After Staining And ESP 155 epoxy |

|

|

Boat Restoration Using ESP 155 solvent based epoxy sealer and primer Find this epoxy on our favorites page |

|

|

Epoxy Bilge Painting Project Click Here.

Yet another rotten plywood boat repair: The Restoration of the famous

Leaf blower Powered Dinghy

epoxy rot repair project

Index of Boat Repair Web Sites - Click Here epoxy boat repair

Tips and Tricks / Boat Repair reference guide / Notes 101 - Click Here

Knowledge is Power - We like informed consumers!

Learn the basics of epoxy at our educational EPOXY 101 page - Click Here.

Finally, email us back with your questions or comments before you buy - EMAIL HERE

|

Everyone Pays Distributor Prices for our Basic No Blush (tm) Epoxy First the basics: Four things you need to know about marine epoxies

2) The 'standard' epoxies will 'blush' produce a waxy surface film during curing. All the vendors offer better, more expensive, non blushing marine epoxies. Progressive Epoxy (that's us) sells only non blushing marine epoxy (Basic No Blush ™ and Premium No Blush™ , our non hazmat to ship version). 3) Most epoxies are sold through agents, resellers and distributors. Distributors usually get the epoxy at 50% (40%-60%) off the list price. They double the price and sell it to end users like you. So most epoxies are sold by the manufacturers at 'half price' or 'distributor pricing' to distributors who mark it up and resell it. PROGRESSIVE EPOXY POLYMERS does not use distributors or resellers. You can only get Basic No Blush epoxy directly from us. Compare and you will find our prices are 50% less than the end user prices our competitors list. Our epoxy is equal or better in quality - our prices are 'distributor prices' for everyone. If we used distributors we would need to vastly increase our prices to our customers to match the 100% markup added by distributors. Call it 'distributor pricing for everyone' or ' half price' epoxy - whatever floats your boat!

MAS EPOXY (their Flag Non Blushing Epoxy (1.5 gal unit - approx. $178.98) https://www.masepoxies.com/users/0142C6E0-CF1D-CEE2-59ED58C41CE094DA/library/files/2010%20%20retailjan%201%202010.pdf SYSTEM THREE (their non blushing Silver Tip Epoxy (1.5 gal unit - approx. $175) https://www.systemthree.com/store/pc/SilverTip-Laminating-Resin-c10.htm WEST (their non blushing epoxy/207 cure (1.31 gal unit - approx. $169.16) https://www.westsystem.com/ss/price-list/ PROGRESSIVE EPOXY POLYMERS (epoxyproducts.com & epoxyusa.com - that's us!) Basic No Blush Epoxy (1.5 gal unit - approx. half the price of our competitors) https://www.epoxyproducts.com/1_marineresins.html ... BUY NOW at our second alternative (simple!) web site: www.epoxyusa.com ... We also have the web's largest floor epoxy site and leading pour-on bar top epoxy.

RAKA (a low price epoxy seller - resin and 305 non blushing resin (1.5 gal - 6 quart kit - approx. $105) https://www.raka.com/epoxy_kits.html

|

|

These are several epoxies/products I couldn't imagine not always having on hand... Wet Dry 700 (tm) - epoxy paste that works underwater. Use to glue/fill/patch - marine epoxy catalog - home/industry epoxy cat. - order/simple web site 2. ESP 155 (tm) - solvent thinned epoxy sealer, tie coat etc. (not for sale in S. Calif) marine epoxycatalog - home/industry epoxy cat. Aluthane (tm) - aluminum filled moisture cured urethane - amazing paint product - Aluthane MCU aluminum paint now as its own web page. Basic No Blush (tm) marine epoxy - if you work on boats, this is the best epoxy at the best price. marine epoxy catalog - order/simple web site 2. |

|

The Marine Epoxy Everything Guide Everything from user reviews, repair examples, pricing issues and vendor evaluation tips

Basic No Blush Marine Epoxy Product Page Basic No Blush 12 oz Marine Epoxy sampler Marine Epoxy Catalog page (multiple epoxies) Basic No Blush Marine Epoxy User Reviews / Feedback How To Evaluating Marine Epoxy brands and Vendors Marine Epoxy prices - what it really costs! Marine Epoxy amine blush - what is epoxy Blush? Dinghy Marine Epoxy boat repair case study Stitch and glue Marine Epoxy construction Progressive Epoxy Polymer's marine web site Massive site of Internet boat links

|

Inside Our Marine Catalog:

Section One TWO PART MARINE EPOXIES- CLEAR EPOXIES

basic no blush epoxy, premium no blush epoxy, esp 155 epoxy, low v epoxy

Section Two FILLERS THICKENERS ADDITIVES

fumed silica; microsphere/balloons; poly fibers; graphite, wood flour; EZ thick; rock flour

Section Three THICKENED EPOXIES - EPOXY PUTTIES, ETC.

wet/dry 700; splash zone; epoxy cream; splash zone a-788

Section Four TWO PART EPOXY PAINTS (barrier coats)

corro coat FC 2100; water gard 300; CM 15; liqua tile 11 72 potable water; rough coat; water prime

Section Five URETHANES AND NON-EPOXY COATINGS Aluthane (aluminum coating); LPU Marine; india spar varnish; acrylic poly uv plus, polyester poly

Section Six NON-SKID DECK COATINGS

walnut shell,; s15

Section Seven MARINE REPAIR PRODUCTS

pipe wrap; fiberglass tape (cloth); Capt. Tolley's Creeping Crack Cure

Section Eight MISC. MARINE PRODUCTS

short nap rollers; TA 661 (solvent free epoxy clean-up); 1 inch foam brushes; 2 inch bristle brushes; tongue depressors

Questions? / Phone order? / EMAIL / CALL 603-435-7199 EST / BUY ONLINE

GOOGLE SITE SEARCH - Click here Epoxy specific site search

Click here - YouTube video. Learn about Progressive Epoxy Polymers Inc.

Click here - Dozens of boat repair info links across the internet. - (everything is here!)

THREE MUST READ WEB PAGES

MPRICES - 2 part marine epoxy pricing issues - CLICK HERE -

MEPOXIES - comparing 2 part clear marine epoxies - CLICK HERE - (you are here already!)

EVAL4U - how to evaluate your marine/non marine epoxy vendor - CLICK HERE -

|

Progressive Epoxy Polymers' Paul Oman solo sailing his former Coronado 25, "Temptress " on Galveston Bay - early 1990s |

Epoxy Only Web Google Search

#1) Google

Everything Epoxy Searches

#2) Google

Marine Epoxies Searches

#3)Google

Floor Epoxy Searches View

our Progressive Epoxy Products, Inc.

|

|

|

||

|

site master |

protagonist |

ground zero |