PROGRESSIVE EPOXY POLYMERS, INC.

Nothing but Quality Products at Good Prices, Great Customer Service, and Lots and Lots of Helpful Information

and NO SALES TAX - You are shopping in TAX FREE New Hampshire

CALL 603-435-7199 (or email).We are the only technology based coating/epoxy/resin company that actively encourages your phone calls, not just during our East Coast work hours but also after/before hours, evening, weekends and even holidays. We're available when you are. We form a personal relationship with our customers and freely share technical information, how to-advice, product information and tips-and-tricks. Speak with a non-salesman technical professional with over 25 years of experience in the resin/coating/epoxy industry (no newbie staffer on the phone lines!). Floors, tables, boats, leaks, rot repair. We handle it all! We are an 'always available,' one-on-one, technical/scientific, coating company (watch our video). We are NOT one of those fluffy/slick mass sales firms the dominate the internet selling cheap third party (made in China???), low end epoxies and coatings with no real knowledge of what they are selling and quotas to sell to as many people as possible. 603-435-7199 (east coast time).

PRIMARY STORE LINK --- TOP SELLING PRODUCTS --- EPOXY GURU HELP SITE --- EPOXY DATA SHEETS

.CONCRETE CEMENT GARAGE SEALER

Concrete Sealing Moisture

control product options

Choosing the Right Concrete Sealer article

Your Host and Tour Guide:

Paul Oman, MS, MBA - Progressive Epoxy Polymers, Inc. (floor epoxies, marine epoxies, underwater epoxies, repair epoxies)

Member: NACE (National Assoc. of Corrosion Engineers), SSPC (Soc. of Protective Coatings)

"Professionals helping Professionals"

PROGRESSIVE EPOXY POLYMERS, INC.

|

PAGE AND SITE NAVIGATION |

|||||||||||||||||

Epoxy Floor Links Page ====> This 'Linked To' concrete sealer Sub-Page

No Sales Tax applied. Save Money, you're shopping in Tax Free New Hampshire

MEMBER: Internet Epoxy Confederation (IEC - CLICK HERE TO VISIT) -- "Where Professionalism Still Matters"

We've been selling epoxy - marine epoxy (boat building - wood / fiberglass repair) industrial coatings - garage paint - underwater epoxies - thick putties - tabletop resins and supplies since the early 1990's |

Epoxy Floor Section in our online catalog - CLICK HERE

|

Concrete Sealing in a Nutshell There are 3 kinds of concrete sealers 1) inexpensive products that contain wax or paraffin dissolved in a solvent. Easy and cheap, but if you use these you will ever be able to coat the surface with any kind of paint or epoxy (you cannot paint on wax!). You cannot remove with solvents, which will just move the wax around. Use this kind of sealer and you are locked out of doing anything else forever. 2) Liquid sealers that are like paint and sit on the surface you are coating. No way you be be certain these will not peel or chip off and they may prevent you from top coating them with other products. 3) Internal concrete sealers, like our Bio Vee Seal. Bio Vee soaks into the exposed concrete and forms crystals within the concrete itself. It leaves nothing (except perhaps some tiny white crystals) on the surface. There is nothing to peel or chip and it leaves the surface as it was, allowing you full options to top coat with any product. Useful links: Bio Vee --- Concrete Sealers --- Industry article on sealing --- basement leaks/sealing --- Floor coating links or call 24/7 for help or to order - 603 435 - 7199 |

Boy, it sure seems that way sometimes, doesn't it? People ask us all the time what to use on new, old, just cleaned

or just poured cementitious surfaces (such as concrete, cement, stucco, most brick and paver stones), and they

question why they should use a sealer. Instead of promoting the latest industry concoction (and it is no accident

that concoction in the dictionary is on the same page as concrete, because there are many different concrete concoctions

out there)

we have realized that the best answers to these questions are a mix of products and techniques that have been used

and have been proven to be effective.

"To make it look nice" is generally the motivating factor for most customers when they contract your

services for the cleaning of concrete. However, don't overlook other selling points when negotiating a job. Dirt

and impurities deteriorate concrete - That's a fact. The larger the surface, the more important it is to maintain

it, due to the cost of repair and replacement. Did you know there is a whole industry for Concrete Repair? Much

of this damage could be prevented with proper cleaning and sealing. Medical and food facilities will have an antiseptic

priority; municipal and heavy traffic areas may have a wear priority. Over the years, the owners of these types

of facilities have already learned from architects and material engineers that clean concrete in conjunction with

a good sealer will yield long life and thus preserve the concrete. They have an obligation to maintain these surfaces,

especially if costly repairs must be made with the taxpayers' money.

If you aren't sealing concrete after cleaning, you're leaving money on the table. In actuality, the concrete finisher

should be sealing the concrete - and not with a temporary cure and seal. Many times, finishers are more concerned

with just getting the concrete down and getting off the job site. In what other field can you get paid on something

that always looks good when you are finished? Then, a roll of the dice will reveal the real outcome.

This actually benefits the Power Washing Industry because, eventually, the customer will call you in to clean.

A good sealer will protect the concrete and make it much easier to clean with less abrasion and harsh chemicals

- a win-win deal for you and the customer.

The main reason that contractors seal concrete is because it is the most practical way to finish your cleaning

job. There are many other reasons to seal concrete, but let's cut to the chase. Consider the scientists who build

bridges, tunnels and skyscrapers. They are using better concrete and workmanship, yet they still mandate a concrete

sealer.

So, what's the deal with homeowners and light commercial business? Unfortunately, they have to learn the hard way

after their concrete experiences a little cracking here, spalling, churting, permanent stains, flaking, curling

and overall general breakdown. Did you know the #1 killer of concrete is salt and water? Well, since the cost of

concrete isn't going down, the reality of replacement and repair is soaking in.

Fact: The #1 used resource on the globe is water. The #2 used resource on the globe is concrete. This seems like

a pretty strong industry that I would want to be a part of in some way.

We have to step up and learn from our past. How long did it take insurance companies to accept the notion of "preventive

health care?" They learned that by promoting preventive methods and curbing an inevitable problem, they were

saving money - a lot of money. Why did it take so long to learn that flossing is three times better than brushing

your teeth? When will customers and contractors learn that sealing is the best preventive action to preserve concrete

and protect from stains and impurities?

We really appreciate you visiting PROGRESSIVE EPOXY POLYMERS, INC. and our web site: EPOXYPRODUCTS.COM. Take advantage of the CONTACT links on this page to ask questions about our products and/or your projects. You can stay in touch with us via our NEWSLETTER (link on our contact page) which is emailed every 6-8 weeks.

|

Epoxy Only Web Google Search |

|

|

#1) Google Everything Epoxy Searches #2) Google Marine Epoxies Searches

#3)Google

Floor Epoxy Searches |

|

View our Progressive Epoxy Products, Inc. |

This current page is all about:

Concrete Sealing Moisture control product options

Choosing the Right Concrete Sealer article

Boy, is this open for scrutinization! Let's start with this: If you don't seal your concrete, we all know what

happens. The impurity sits, it stains, it looks bad, and it will eventually deteriorate the concrete. It also has

the potential of becoming permanent. So, what do you do? You face reality, and the reality is you can't prevent

a stain, but you can manipulate it. In other words, you can make it a topical problem by attacking it intelligently,

as opposed to a substrate problem. Substrate penetration, at some point, becomes irrevocable with possible serious

damage to the concrete from aggressive measures like very high pressure, acids, scarifying, shot blasting, sandblasting

and nuclear explosion. (Just kidding about nuclear explosion, but some power washers can scare us with their cleaning

methods.)

Applying a sealer on cementitious products will vary, depending on the sealer used. We are going to address a water

borne sealer since the EPA is trying to halt the use of solvent base sealers.

In most cases, application is very easy and can be mastered in a short time. It requires the use of low pressure,

and you can use a 15° tip and up, depending how fast you want to walk. It isn't necessarily the sealer that

you need to be extremely familiar with, but the surface. Learn about your surface and that will determine your

rate of application and which mix, pressure, tip and speed you use. In most cases, pump sprayers and backpack sprayers

work well. In larger jobs, you may want to seek a unit that will carry more product but will still get you down

to about 50 psi, if necessary. Here are some additional guidelines to follow:

o Use a general left-to-right motion, while moving from north to south.

o Don't let it form puddles. Sweep it out if necessary.

o With most sealers, avoid overuse.

o The water is just the vehicle, not usually part of the sealing agent.

o Watch for rain, traffic and impurities (both before and after the application) that might inhibit

the reaction that needs to take place in order to get a hold and make the seal.

o Most application procedures are similar, but always refer to the sealer's instructions, as each one may have

a caveat (warning) about their product.

The list of sealers you can use is endless. Everybody has the newest, the best modified or the improved version

of a sealer. They may come in the form of vinyls, acrylics, resins, siloxane, silicates, silicones and more. Some

of these have been proven to be effective, but it will still benefit you to investigate the new stuff. Computers

have made it possible to accelerate test data so that it can be created faster with better test results. You don't

still watch black and white TV, do you ? Maybe some of you do. It was good, and it worked just fine, but you still

can't refute that there is new technology. In the same manner, they have made great breakthroughs in molecular

chemistry that affect surfactants, which in turn affect sealers.

You want a sealer to penetrate into the substrate of the cementitious material. A sealer which coats and lays on

top is screaming, "I'm temporary!" There are not many scenarios where the customers want this, and if

they do, it is your obligation to educate them and talk them out of it.

Typically, a penetrating sealer will penetrate the surface, cause a reaction or third agent, solidify and then

do its stuff. That's part of the problem. Just because the process is similar doesn't mean the chemistry left behind

has endurance. SALT, SALT, SALT! Salt products will usually breakdown somewhere, someway, somehow. I am still waiting

for one that doesn't. Have you ever wondered why some sealers say KEEP OFF GLASS? When salt adheres to the glass,

salt can etch the glass.

Here are some general facts to consider:

o When sealing a smooth finish, the concrete is not going to be as receptive because of the porosity and tightness,

so smaller amounts can be just as effective if you are using the right product.

o With the different strengths of concrete available, additives, slump, temperature, etc., make sure to always

do a test patch. When concrete becomes a universal, consistent product, then we will be able to give a universal,

consistent application procedure. The good news is there are some sealers that are pretty close to a universal

answer.

o Some stone, marble and glazed brick do not receive penetrating sealers very well. Some will. Again, always do

a test.

o Just because it looks tight, doesn't mean it is. Various sealers have different sizes of molecules and can get

the job done. So again, do a test patch. Don't be fooled by a little chalking - this can be overuse and not a true

test for penetration.

o Sealing should be a must for preparation of an epoxy coating. This will help the degradation from the bottom

and will help prevent moisture migration, mold, mildew and accompanying smells. A good contractor should also seal

concrete before hardwood flooring, installation of carpet padding and tile applications.

Chemists have proven that a "like-like" scenario is preferred when applying a cure and seal. In other

words, here is what we see. The contractor comes in, puts down something to cure and maybe seal, with an average

life expectancy of one to nine months. It now becomes the business or homeowner's problem to protect or maintain.

The business or homeowner doesn't know what to do or how to match what is already applied to get the maximum seal.

Even if he does know what has been applied to cure the surface, it may not be suitable for sealing it, and again,

it may not be able to sustain long life.

Your position should be to work with contractors to use a sealer that will pass the ASTM's cure and seal tests,

then offer to follow up with the business or homeowners to clean and seal with the "like (same) sealer"

for the last time. It is a win-win-win deal for the contractor, business or homeowner and you. There is legislation

developing all over the country that is now protecting the consumer more and more. The Attorney General's office

is not going to accept the phrase "That's the nature of concrete. It cracks, churts, etc." from the contractor

and concrete supplier. There will be tests they will have to be passed in order to complete the job, and one of

them will be the necessity of a cure and seal. Contractors will have to upgrade their work to keep from being liable.

This is where you come in after the installation and continue to protect their work.

In closing, when you have questions about sealing concrete, go to an information source with which you are comfortable,

such as the Internet, trade shows, word of mouth and trade magazines. Sealing concrete is as important as painting

your house. Is there some concrete you don't want to seal? Sure! If you can't get concrete clean enough to take

a seal, then a sealer probably isn't the answer. But don't surrender too fast because some methods of surface preparation

are worth the effort for the end result. A good measure for scrutiny can be determining if certain basic tests

are met. Then, there is some comfort in the fact that someone bigger, more knowledgeable and with more money to

spend has done the leg work for you. Ask for the test results. There are many garage-based sealer operations out

there. It can be confusing to determine between a good sealer and a good salesperson. Better products don't always

come from bigger companies. Some of the best sealers available are developed especially for individual applications.

As a general rule of thumb, results you can actually see will give you more comfort than all the test data in the

world.

WOW!

35%

- 40% of all daily online or telephone orders are from existing

customers. That's an amazing 'REPEAT

CUSTOMER" number. 603 - 435 -

7199 ANYTIME 24/7 FOR HELP OR ORDERS

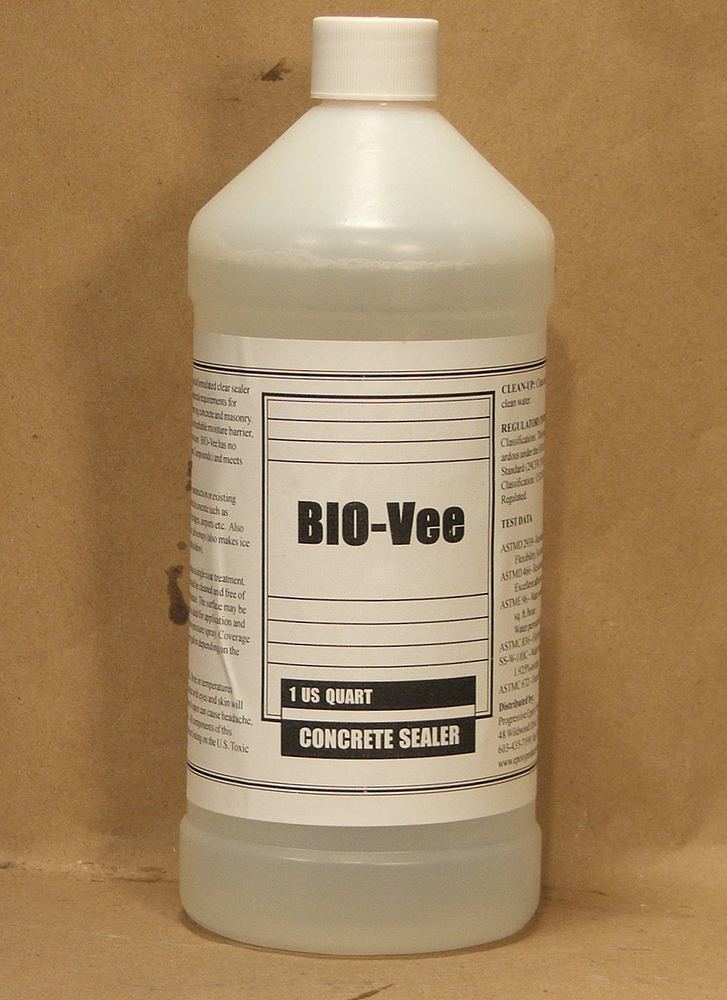

LEARN ABOUT BIO VEE SEAL (tm) concrete sealer - A PRODUCT DEVELOPED BY JAY, AND AVAILABLE FROM US

USED BY ITSELF, IT WILL REDUCE, OR ELIMINATE, MOISTURE MIGRATION THROUGH CONCRETE FLOORS AND WELLS (THROUGH THE CONCRETE ITSELF, NOT WHEN MIGRATION IS THROUGH CRACKS). IT IS USED ON CONCRETE THAT IS ALWAYS A BIT DAMP AND TO END THE 'MUSTY' OR DAMP SMELL IN BASEMENTS, ETC. PERHAPS MORE IMPORTANTLY, BUT LESS OBVIOUS, IS THAT BY REDUCING OR ELIMINATING MOISTURE MOVEMENT THROUGH THE CONCRETE IT INCREASES THE LIKELIHOOD OF A SUCCESSFUL PAINT OR COATING JOB ON THE CONCRETE SURFACE (NOTE: THIS PRODUCT WORKS BELOW THE SURFACE OF THE CONCRETE, IT LEAVES NOTHING ON THE SURFACE). THIS IS BECAUSE MANY COATING FAILURES ARE THE RESULT OF MOISTURE OR VAPOR PRESSURE BUILDING UP ON THE UNDERSIDE OF COATINGS APPLIED TO CONCRETE.

BECAUSE OF THIS, BIO VEE SEAL IS ALSO A RECOMMENDED, BUT OPTIONAL, PRE-TREATMENT TO CONCRETE SURFACES THAT WILL BE COATED WITH SOME SORT OF SURFACE COATING.

WILL SEAL UNCOATED/UNPAINTED STUCCO!

(We

discourage purchasing between Dec. 1 and March 15 due to possible freezing of

this water based product)

FIND THIS/THESE

PRODUCT(S)

IN ONLINE

CATALOG PAGE AND ONLINE

STORE FRONT

Epoxy Only Web Google Search

#1) Google

Everything Epoxy Searches

#2) Google

Marine Epoxies Searches

#3)Google

Floor Epoxy Searches View

our Progressive Epoxy Products, Inc.

|

Bio Vee Seal internal concrete sealer Sampler Kit Bio Vee Seal helps control moisture issues in concrete (moisture migrating up or spills migrating down). It is an internal sealer, forming crystals in the surface void spaces of the concrete. it is not a surface paint like sealer. The 1 quart test unit will cover about 50 sq feet. If you like it, you can then order gallon or 5 gallon units. This product is featured on the GreatThings4u.com website. CLICK HERE to see these products in our online catalog (special purpose epoxies section). |

|

Progressive Epoxy

Polymers, Inc.

|

|

|

|

Frog Pond Hollow48 Wildwood DrivePittsfield, NH 03263

|

|

Home of the Annual Pittsfield Balloon Rally

|

|

|

|

|

|

|

|

||

|

site master |

protagonist |

ground zero |