PROGRESSIVE EPOXY POLYMERS, INC.

GOOGLE SITE SEARCH - Click here

Nothing but Quality Products at Good Prices, Great Customer Service, and Lots and Lots of Helpful Information

and NO SALES TAX - You are shopping in TAX FREE New Hampshire

APPREHENSIVE?

New to Epoxies? (They can be $$$). Let's talk (603 - 435 - 7199 or EMAIL) and put yourself at ease with a 1 on 1 conversation about your project, which products will work best for you, and how to use them. After purchase "handholding", support, and encouragement are also available anytime. We freely share our 20 plus years of epoxy experience and problem solving experience. If our owner, Paul Oman, is not available he will return your call quickly. Emails are answered all day long. Without potential customers, repeat customers, and friends like you that want some free, quick advice, New Hampshire based Progressive Epoxy Polymers, Inc., a Better Business Bureau member, would not exist. Thank you in advance and thank you for visiting epoxyproducts.com. We appreciate you interest in our company.

PRIMARY STORE LINK --- TOP SELLING PRODUCTS --- EPOXY GURU HELP SITE --- EPOXY DATA SHEETS

Buy With Confidence

Better Business Bureau Accredited

company

TWO PART EPOXY PAINT (coal tar epoxy)

largest selection of epoxy paints on the internet

Coal Tar Epoxy Paint Info Page

we no longer sell coal tar epoxy

We offer a modern Replacement

Coal tar epoxy paints are essentially a mix of coal tar and epoxy resins (and not all epoxy resins are the same). Coal

tar epoxies were at their peak of popularity in the 1960's (???) through about 1990. After that, non-coal tar epoxies

replaced coal tar epoxies due largely to health concerns over long term exposure and direct contact (by coating

applicators) to the ‘tar'.

Coal Tar epoxy paint alternative is our black CM 15 epoxy paint - find both Coal Tar and CM 15 CLICK HERE

Coal Tar Epoxy Paint Intro & alternatives -- solvent free coal tar two part epoxy

Solvent Free Coal Tar Epoxy Paint

- Commercial grade

Your Host and Tour Guide:

Paul Oman, MS, MBA - Progressive Epoxy Polymers, Inc. (floor epoxies, marine epoxies, underwater epoxies, repair epoxies)

Member: NACE (National Assoc. of Corrosion Engineers), SSPC (Soc. of Protective Coatings)

Board member: Friends of the Suncook River - 501(c)(3) non profit ----- Founder: Friday Night Paddlers .

"Professionals helping Professionals"

In business since 1994

PROGRESSIVE EPOXY POLYMERS, INC.

|

PAGE AND SITE NAVIGATION |

|||||||||||||||||||||||||||||||||

Epoxy Education Links Page ====> This 'Linked To' Coal Tar Epoxy Sub-Page

No Sales Tax applied. Save Money, you're shopping in Tax Free New Hampshire

MEMBER: Internet Epoxy Confederation (IEC - CLICK HERE TO VISIT) -- "Where Professionalism Still Matters"

We've been selling epoxy - marine epoxy (boat building - wood / fiberglass repair) industrial coatings - garage paint - underwater epoxies - thick putties - tabletop resins and supplies since the early 1990's |

"You provide outstanding products, and Fantastic Support. Thank You." Brian S. (call 603 435 7199 anytime)

"Thanks for all your advice, tips & moral support concerning my project. It turned out beautiful. Quality people backing a quality product is the only way to go!" Joe

A few years ago I searched the Internet looking for information about coal tar epoxy

paint. I found lots of product

pages, but nothing about why and where coal tar epoxies should/could be used in place of regular epoxies. What

are the Pro's and the Con's of coal tar epoxy paint? I have now learned these things and wish to share the information.

Please note that our company, Progressive Epoxy Polymers, Inc., offers a coal tar to the line of epoxies

and clear coat products that we sell. It is a solvent-free coal tar epoxy of very good quality (using the most

modern epoxy components to a 38% coal tar base). It sells in 2 gallon kits. More information and links to our company

web site are at the end of this document. So much for the advertisement/disclaimer, now the information promised

above!

Background History

Coal tar epoxy paints are essentially a mix of coal tar and epoxy resins (and not all epoxy resins are the same). Coal

tar epoxies were at their peak of popularity in the 1960's (???) through about 1990. After that, non-coal tar epoxies

replaced coal tar epoxies due largely to health concerns over long term exposure and direct contact (by coating

applicators) to the ‘tar'.

Advantages of Coal Tar Epoxy Paint

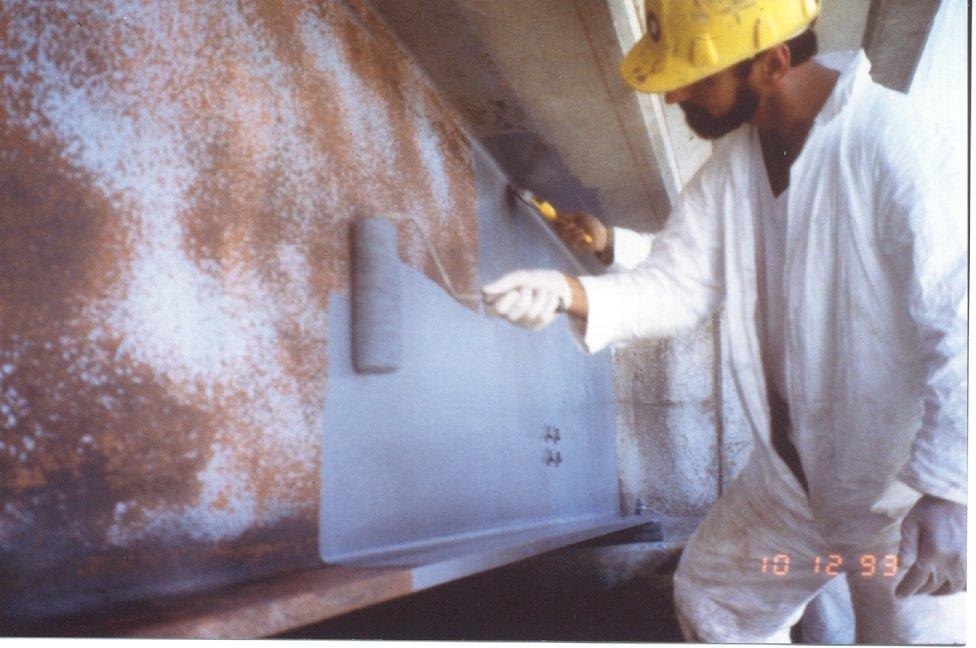

Coal Tar epoxies are inexpensive compared to most non-coal tar epoxies. The offer considerably more flex (or elongation) then regular epoxies. This makes them useful on garage floors where turning/spinning tires will ‘stretch' the epoxy, as well is in situations with a lot of expansion and contraction. Coal Tar epoxies are also famous for protection from moisture, both in the water (such as barge hulls) and when buried underground (such as pipelines and underground tanks). A key advantage of coal tar epoxies is its ability to bond to oily surfaces (thanks to the hydrocarbon nature of the ‘tar').

Disadvantages of Coal Tar Epoxy Paint

Coal Tar epoxies smell like tar/asphalt and leave an asphalt like stain on your hands, etc. when working

with the un-cured epoxy. It only comes in a tar black color. Coal tar is not something you want to handle on a

regular basis over a long periods of time.

Most or all of the other disadvantages of coal tar epoxies are often more about the epoxy side of the mixture rather

than the coal tar side. Issues here can include solvents in the product, and poor resistance to UV (becoming more

brittle and chalky), are the ones that come to mind. There are also reports that weathered

coal tar is difficult to recoat or topcoat. At least some coal tar epoxies appear to leave behind an oily

layer as the epoxies weather away and this layer makes top coating - recoating difficult or impossible. The coal

tar that we use does not appear to have this problem, at least it hasn't been reported to me yet.

Misc. Information

Coal tar epoxy paint (at least the version we sell) can be topcoated with regular paints. It can also be used with colored quartz sands or vinyl chips for decorative epoxy floors -just like non-coal tar epoxies are used.

When and Where I Would Recommend Coal Tar Epoxy Paint

The less costly coal tar epoxypaint is often a better quality coating than an equally priced non-coal tar epoxy. A good quality (and more costly) non-coal tar epoxy will perform equal or better than a coal tar epoxy and will be available in colors other than black. The odor of coal tar epoxies (at least the one we sell) is not really that strong, still, I would use it in a well ventilated area or outdoors. The coal tar epoxies that I have tried (several brands) all seemed flow of the paint brush more smoothly than solvent free, non coal tar epoxies. This makes it a bit easier to apply and probably less likely to leave behind thin spots or ‘pinholes' in the coating surface.

Because coal tar epoxies will bond better than other epoxies to oily surfaces, they are more likely to remain

bonded to ‘degreased' garage or work floors. I would consider their use, perhaps thinned with solvent, as a sealer/primer

over such areas. The coal tar epoxy can then be topcoated with other coatings.

The much flex (bend) and elongation (pull) of coal tar epoxies (3 to 10 times the amount of regular epoxies and

the only product we carry with BOTH flex and elongation - each about 25%) ) is its greatest characteristic and

the case presented regarding the benefits of this property when used on garage floors, garage ramps, etc. where

there is lots of rubber tire traffic, makes logical sense to me. However, I have not heard of less flexible, non

coal tar epoxies failing in these situations either. Coal tar's ability to withstand moisture (old time sailors

sealed their boats with tar pitch) is another important plus, but I think good quality, non coal tar epoxies offer

just as good moisture sealing.

Coal tar epoxy paints are ‘out of style' but their usefulness has not diminished. A good quality coal tar epoxy offers

a price to performance ratio that is hard to beat. Their greater flex is a real plus (although not as important

in may situations as it might seem), while their messy tar staining and smell are a downside consideration. I think

the decision to use coal tar epoxy can be made more on personal choice than on a point by point technical comparison,

sort of like decision between an apple or orange with your lunch. Just remember that all coal tar epoxies (like

all other epoxies) are not the same.

We really appreciate you visiting PROGRESSIVE EPOXY POLYMERS, INC. and our web site: EPOXYPRODUCTS.COM. Take advantage of the CONTACT links on this page to ask questions about our products and/or your projects. You can stay in touch with us via our NEWSLETTER (link on our contact page) which is emailed every 6-8 weeks.

This current page is all about:

Coal Tar Epoxy Paint Intro & alternatives -- solvent free coal tar two part epoxy

Solvent Free Coal Tar Epoxy Paint - Commercial grade

|

|

WOW! 35% - 40% of all daily online or telephone orders are from existing customers. That's an amazing 'REPEAT CUSTOMER" number. |

|

603 - 435 - 7199 ANYTIME 24/7 FOR HELP OR ORDERS |

|

|

|

|

Coal Tar epoxy paint alternative is our black CM 15 epoxy paint - find both Coal Tar and CM 15 in our catalog - CLICK HERE

Additional product information/mentions about BASIC NO BLUSH can also be found at the following site(s) - http://www.paints-coatings-epoxies.com/a_bioclear.html

All coal tar epoxy paints are not the same!

Materials Performance magazine dec. 2002 - q&a section page 39

"Coal tar epoxy paint failure"

RE: coal tar coating failure in a sewer pump station steel wet well. After suitable surface preparation surface

was coated with two coats of a polyamide coal tar epoxy. Failure of the coating was at a 5 inch zone at the top

of the high liquid level. Failure consisted of softening and swelling, not blistering. The authors go on to quote

from "Corrosion Prevention by Protective Coatings," a text by C.G. Munger. Munger states that CTE (coal

tar epoxies) coatings are most effective in the sewage industry. However he qualifies this by stating that the

amine cured CTE system is essential because of the bacterial attack on the polyamide curing agent.

The coal tar epoxy paint offered by Progressive Epoxy Polymers IS an AMINE cured system and not the problem causing amide

system described above. Our coal tar epoxy is also solvent free (0% VOC).

This is not your Grandfather's Coal Tar epoxy! It is a very high end, solvent free, cycloaliphatic based epoxy system coal tar epoxy

| CLASSIFICATION | PROFESSIONAL QUALITY "B GRADE" MAINTENANCE COATING - THIS IS A HIGH QUALITY COAL TAR EPOXY |

| % VOC | 0% VOC, 100% SOLIDS |

| SHIPPING/EXPORTING | HAZMAT - ORM-D TO SHIP. CANNOT BE SHIPPED OUTSIDE THE USA OR BY AIR |

| VISCOSITY | BRUSHABLE, ROLLABLE |

| STND COLORS | BLACK |

| WET APPLICATION | APPLIED TO DRY SURFACES |

| MIX RATIO | 1 TO 1 BY VOLUME |

| STND PACKAGING | STANDARD PACKAGING IS 2 GALLON UNIT |

| MISC. INFO | |

| PRIMING | |

| Order this two

part

EPOXY Product

NOW from our large Primary web store |

Daniel Skira -- Skira Yacht Design wrote (5/2010):

I just received my two quart of coal tar epoxy I ordered. What I really like is the literature and all the information

you put with the package. It is very useful. I used normal coal tar until now, and look forward to try your product.

VENDOR COMMENTS:

Hi Daniel – Thanks for the kind words. Yes, I too like the coal tar epoxy - rolls on nicely. But coal tar epoxies

have other issues (see www.epoxyproducts.com/coaltar.html - soft/flexible, may not be able to paint over especially

if old and sun weathered, etc.) and I often recommend cm 15 epoxy as an alternative to the coal tar.

If you notice a difference with our coal tar epoxy it would be because of the high end epoxy part of the coal tar

epoxy we use. Most coal tar epoxies have a reputation for using very low end epoxy.

Daniel Skira -- Skira Yacht Design wrote (5/2010):

Paul, – The one to one mix is absolutely the way to go. Fantastically easy. The product is very good, goes like

a charm on wood, dry nicely without any shrinkage. I built the boat outside, at 50F no problem even we had light

rain, no problems.

I really like your coal tar epoxy. A real time saver compared to the classic one. The quality of the coal tar is

the same as the high end one component I used for almost 30 years. But yours dries! No need to wait one month anymore!

No need to boil it either like the other one, to have a good penetration. Your coal tar epoxy seams to have a very

good penetration. I even used on some larges holes on the keel, and it worked like a charm. Impossible to do the

same with the non-epoxy one. I will be sending another order. I am hooked on yours! I will probably paint the underwater

part of the hull with your coal tar epoxy. Many thanks.

Daniel Skira -- Skira Yacht Design wrote (5/2010):

Hi Paul – Just painted with regular oil based painting on top of your coal tar epoxy without any preparation. Dry

neat, and seems to bond. I sanded two coats of coal tar epoxy with a belt sander and 36 grit belt, but with a light

handling of the machine. Perfect, no problems. Painted on top with regular oil based paint. No problem.

So my underwater hull will be painted with your coal tar epoxy. Then I will apply a coat of antifouling. Not the

sides since I know the problem of epoxy and the sunshine. The elongation of you coal tar is a perfect match for

my wooden hull.

All my best. - > Daniel

Daniel Skira -- Skira Yacht Design wrote (5/2010):

Hi Paul – After curing for 7 days, the coal tar epoxy I applied to a steel bar was even not touched. I used a heavy

hammer to bend the steel bar. The secret is let it cure at least 7 days and it is hard and flexible. It is the

greatest coal tar epoxy I ever tried. You can post my trial on your website. This an amazing product. But I repeat,

the curing time is mandatory. Sometime people think epoxy is immediate, they are wrong. I will come for more, the

hull will be primed underwater with your coal tar epoxy.

All my best – Daniel

CLICK HERE TO GOTO OUR USERNOTES SECTION: FEEDBACK FROM FOLKS WHO HAVE USED THIS AND OUR OTHER EPOXIES.

Quick Purchase this product at our simplified www.epoxyUSA.com site

ON-LINE CATALOG HOMEPAGE.

Inside Our non-marine, commercial, DIY Catalog:

corro coat FC 2100; water gard 300; CM 15; crack coat™; liqua tile 1172 potable water; water prime

Find Corro Coat FC 2100 and Water Gard 300 epoxy in our Best Selling - fix anything Catalog

water bond (water based); industrial floor epoxy; bio vee seal; walnut shell; rough coat grit filled epoxy floor paint; epoxy clear top resi

wet/dry 700; splash zone A-788, epoxy cream; splash zone a-788

Find Wet Dry 700 epoxy in our Best Selling - fix anything Catalog

low V epoxy; basic no blush; ESP 155; Bio-Clear 810; epoxy clear top resin

Find Low V, Basic No Blush, and ES 155 epoxy in our Best Selling - fix anything Catalog

Aluthane moisture cured urethane; Acrylic Poly UV Plus and other 2 part polys ; Capt. Tolley's creeping crack sealer; india spar varnish;

Find Aluthane in our Best Selling - fix anything Catalog

fumed silica; fiber fill; micro balloons/micro-spheres; graphite; wood flour; EZ thick, rock flour;

water activated pipe wrap; TA 661 solvent-free epoxy brush cleaner; fiberglass tape/cloth

short nap epoxy rollers; epoxy/stone deck resurfacing roller; 1 inch foam brushes; 2 inch bristle brushes; tongue depressors

Questions? / Phone order? / EMAIL / CALL 603-435-7199 EST / BUY ONLINE

GOOGLE SITE SEARCH - Click here Epoxy specific site search

Click here - YouTube video. Learn about Progressive Epoxy Polymers Inc.

EVAL4U - how to evaluate your epoxy vendor - CLICK HERE -

These are high end epoxy paints with years of commercial and industrial history - now available in smaller units for smaller projects and DIY activities

Used on tanks, pits, sumps, foundations, boat hulls etc.

Corro Coat FC 2100 A

The only Epoxy Paint reinforced with Kevlar (tm) microfibers and feldspar ceramic for an incredible hard and tough product plus enhanced abrasion resistance. You will not find a better epoxy paint for your tough, demanding project. Non hazmat to ship - so flies anywhere you need it. This super performance epoxy has its own web page - FC2100.

Can be applied Underwater too! Nothing else like it in the market. Manhole and tank lining system.

Water Gard 300™

High end end, solvent free epoxy paint available in blue or white. This version has a little bit of flex to it. - 2 to 1 mix ratio. Can be applied underwater (ie. spa and swimming pool repair). Manhole and tank lining system. A very popular marine barrier coat epoxy. - potable water version is NSP `120 (below). Learn more.

Water Gard 300 coating a boat bilge

before and after pictures

NSP 120

A potable water version of the Water Gard 300 solvent free epoxy paint available in blue or white. This version has a little bit of flex to it. - 2 to 1 mix ratio. Approved for tanks over 800 gallons. Learn more.

Coal Tar epoxy paint

A very high quality, solvent free, black coal tar epoxy. This version has a little bit of flex to it. - 1 to 1 mix ratio. Only found in our industrial catalog. This is the GOOD coal tar epoxy - Learn about coal tar epoxies.

6/16/10

Hello Paul,

I own a 1986 Hunter Legend 40 sailboat. I bought the boat in the fall of 2004 and had the hull below the waterline

was sandblasted in the spring of 2005. The hull was then coated by the boat yard with a VC-Tar coal tar epoxy at

great expense. by the fall of 2005, barely 5 months later, the hull started showing signs of osmosis again below

the waterline. This was likely due to the very thin coat of coal tar applied by the boat yard.

In the spring of 2006 I proceeded to sand off the VC-Tar from the entire

hull and applied five coats your coal tar expoxy. Once dry, I applied a hard antifouling paint. The coal tar has

held up beautifully and is still in good condition after 5 years. The osmosis has not resurfaced, indicating that

the coal tar is doing its job as a barrier coat.

My only dissapointment is that the curing time can be lengthy and if you apply antifouling paint over the coal

tar before it is fully cured, the paint will craze. That said, I have since sanded the antifouling paint off and

subsequent paint coatings hold up well on the rougher surface.

Regards, Fulvio

CM 15

A top quality solvent based epoxy paint with extremely long pot life and plenty of flex (unlike most brittle epoxy paints). Used as an epoxy paint/barrier coat and places where good flex is required (often over wood)

find these epoxy paints in our COMMERCIAL - DIY CATALOG

find these epoxy paints in our MARINE CATALOG

Nothing but Quality Products at Good Prices, Great Customer Service, and Lots and Lots of Helpful Information

|

Epoxy Only Web Google Search |

|

|

#1) Google Everything Epoxy Searches #2) Google Marine Epoxies Searches

#3)Google

Floor Epoxy Searches |

|

View our Progressive Epoxy Products, Inc. |

|

|

|

||

|

site master |

protagonist |

ground zero |

Coal Tar Epoxy Paint Intro & alternatives -- solvent free coal tar two part epoxy

Solvent Free Coal Tar Epoxy Paint

- Commercial grade