PROGRESSIVE EPOXY POLYMERS, INC.

PROGRESSIVE EPOXY POLYMERS, INC.

Nothing but Quality Products at Good Prices, Great Customer Service, and Lots and Lots of Helpful Information

and NO SALES TAX - You are shopping in TAX FREE New Hampshire

.

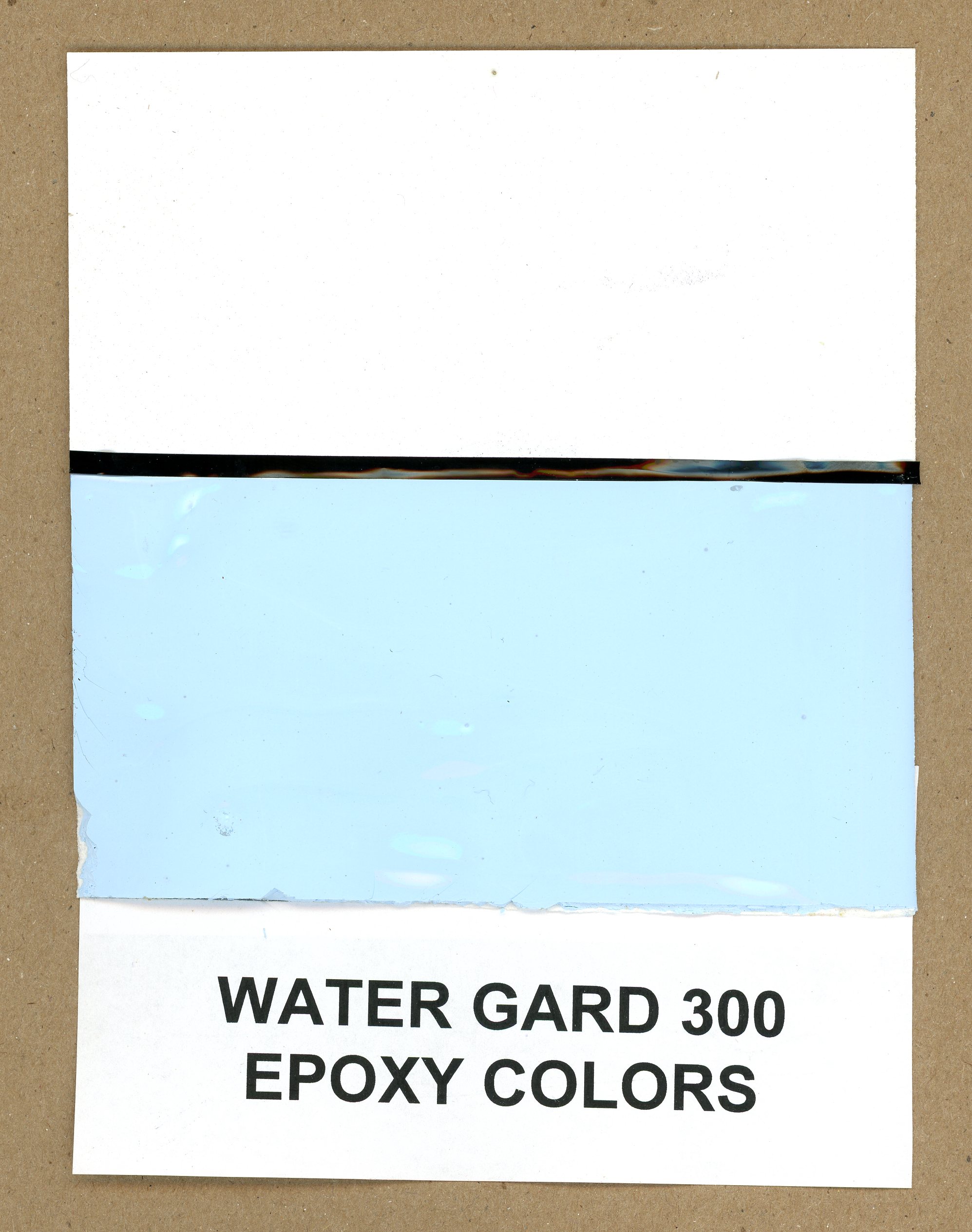

We believe our Water Gard 300 epoxy is the BEST Barrier Coat epoxy resin system you can apply to your boat. It is the only "Nuclear Grade" as well as an epoxy adduct resin system you can purchase for your boat. A step above other epoxies in terms of properties and performance (which is what you look for in barrier coat epoxies). Call or email and we can talk about your boat and why our barrier coat epoxies are the best you can buy. ABSOLUTE BEST SOURCE for epoxy information, options, USA made products, 24/7/365 help, and support. (EMAIL 603 435 7199)

Read about the "Nuclear Grade" time tested, one coat, epoxy barrier coat alternative (Water Gard 300)

Read about the EPOXY ADDUCTS for your best performing barrier coat epoxy(Water Gard 300)

Boat Blister Repairs - Fiberglass

hull Epoxy Repair - Boat Pox

DIY fixes for repair of fiberglass boat gel coat hull blisters -- MARINE EPOXY

Your Host and Tour Guide:

Paul Oman, MS, MBA - Progressive Epoxy Polymers, Inc. (floor epoxies, marine epoxies, underwater epoxies, repair epoxies)

Member: NACE (National Assoc. of Corrosion Engineers), SSPC (Soc. of Protective Coatings)

Board member: Friends of the Suncook River - 501(c)(3) non profit ----- Founder: Friday Night Paddlers .

Boat U.S. member since 1980

Former Sailing Instructor -- 1976 Yachting Magazine -- Jr. Article Writing contest 1st place winner -- Boat builder -- Founder: Friday Night Kayaking Club

|

13 different marine epoxy -polyurethane coatings (www.epoxyproducts.com/ |

|

PROGRESSIVE EPOXY POLYMERS, INC also visit |

We are the only technology based coating/epoxy/resin company that actively encourages your phone calls, not just during our East Coast work hours but also after/before hours, evening, weekends and even holidays. We're available when you are. We form a personal relationship with our customers and freely share technical information, how to-advice, product information and tips-and-tricks. Speak with a non-salesman technical professional with over 25 years of experience in the resin/coating/epoxy industry (no newbie staffer on the phone lines!).

** Quick EMAIL / ph 603.435.7199 EST / Google SITE SEARCH / Buy On-line TWO STORES / Goto Contact PAGE / Web Product CATALOG / Progressive Epoxy HOMEPAGE / View our VIDEO / Navigation Bar REPLACEMENT / Data and MSDS PRODUCT INFO / Epoxy Guru HELP SITE / Top Selling Products - FAVORITES * *

Consider an ESP 155 a solvent based epoxy primer even if you are skipping the barrier coat and going direct to bottom paint, or using some other barrier coat epoxy. It is very thin and quick and easy to apply (2 quart kit covers about 150 sf). It is good insurance if you are taking an older hull back to the fiberglass/gel coat surface.

|

Why Water Gard 300 epoxy is the BEST in its class: 1. Performance boosted epoxy ADDUCT (the other 'stuff isn't) 2) can be applied underwater 3) zero VOC - no environmentally unfriendly solvents 4) cycloaliphatic formulation (the other 'stuff isn't) 5) not too thick, not too thin, 1 coat epoxy paint 6) special high-end curing agents allow shipping by air 7) strong user support / feedback (603-435-7199 or email) 8) use with or without an epoxy primer (ESP 155) 9) 24/7 support 10) popular bilge coating too! (see case study) NO SALES TAX - You are shopping in TAX FREE New Hampshire - New England's "Granite State" |

In A Nutshell (summary):

|

Barrier Coat 101 - IN A NUTSHELL

STEP 1) Prep the hull removing most or all of the existing paints and coatings. STEP 2) Fix any blisters as per epoxyproducts.com/blister4u.html using Low V epoxy and Wet Dry 700 kevlar (tm) underwater epoxy (the Wet Dry 700 is one of our epoxies used to save the sunken yacht Banshee it can be applied underwater). STEP 3) Optionally prime / seal the hull with ESP 155 epoxy primer (not for sale in S. California). Generally used to help sealing and bonding on abrasive blasted (i.e. 'damaged') hulls, sun weathered hulls, or old fiberglass. About 75% of owners prime/seal with ESP 155. This is an important consideration STEP 4) Using short nap rollers apply a coat of epoxy barrier paint (yielding about 8 - 12 mils of thickness - most sources recommend 10-12 mils). Use CM 15 epoxy on hulls that have a bit of flex or if applying in hot weather (CM 15 has a long pot life and more than ordinary epoxy flex. - coverage 1 gal covers about 150 sf). Most owners use our Water Gard 300 epoxy paint sold in light blue or white - 3 gal unit covers about 400 sf. Also used as a bilge coating). Owners also use our gray, Kevlar (tm) reinforced, epoxy paint called Corro Coat fc 2100A. A 1.5 gal unit covers about 150 sf. It is also one of the other epoxies (applied with fiberglass cloth underwater) to save the sunken yacht Banshee. The Water Gard 300 and the Corro Coat fc 2100A also make a good bilge coating - see a Water Gard 300 user example. STEP 5) 'Scratch up' the surface (recommended) and apply your bottom paint as per manufacturer's direction. Or consider a copper epoxy option (fine copper powder mix into a thin epoxy - our Low V epoxy - and applied to the hull. Get the copper (about 5 pounds per 1.5 gal epoxy kit) on EBAY. Top List Of 14 Reasons for Using Our Water Gard 300 Barrier Coat Epoxy (most apply to the FC2100A epoxy and CM15 epoxy too)

1) One coat Coverage (excluding optional ESP 155 primer). Your time is worth a lot and products that require multiple coats were never designed for barrier coating. 2) Quotes and info on this page show years of happy users - a proven Barrier Coat epoxy. 3) At one time this product, under a different label, was approved for potable water tanks over 800 gallons. This is a very pure resin system, no crappy fillers or additives. (our new potable water epoxy is approved for tanks as small as 50 gallons - an amazing size breakthrough). 4) 24/7 phone and email support (go ahead, call right now 603-435-7199). Need to talk on Christmas Day? No problem. Will they answer/call back on Saturday or Sunday? 5:30 AM before you head off to work? We will. 5) This product can be applied underwater with or without fiberglass cloth. Keep left-over product on board. It could save your boat (or your life) in an emergency (along with WET DRY 700 epoxy). 6) This is not just an epoxy paint. It is a CYCLOALIPHATIC epoxy adduct paint which provides higher quality properties across the board. You won't find any other epoxy adduct formulations available for your boat. 7) Made and sold in the USA by a group of small, entrepreneurial companies. If you want to support you neighbors and small local businesses, this is your opportunity. 8) Other uses around the boat: bilge coating, icebox, engine room/battery box coatings. Emergency repair kit. 9) We are a better product. Read "Why you should use our Water Gard 300 instead of the competitor's epoxy below. 10) We appreciate your interest and thank you sincerely for your business! 11) Do the other guys have this on their sites? 12) Tax Free New Hampshire location - No Sales Tax applied 13) A nuclear grade epoxy coating (under an earlier name - see link below). You don't use crappy products in nuclear facilities. You won't find any other barrier coat epoxy being held to this high of a performance and purity standard. 14) Under a different label approved for fish farm applications in Canada. This is the best water quality, non polluting, marine life safe epoxy you can put on your boat. MAKE SOME FISH HAPPY - USE WATER GARD 300 ON YOUR HULL!

NOTE: the FC2100 epoxy is a Kevlar (tm) reinforced epoxy coating that can also be applied underwater. The CM15 epoxy is a warm weather coating with lots of flex for an epoxy. Why you should use our Water Gard 300 Barrier Coat Epoxy instead of the Leading Competition's Epoxy Product Our leading barrier coat epoxy competitor requires application of five coats of their solvent based epoxy just to reach a minimum mil thickness. Five coats - that is outrageous! That's a lot of product and time wasted. (solvent free Water Gard 300 is a one coat epoxy paint). Requiring multiple coats also tells you it is a solvent based, obsolete "Long Ago" industrial epoxy. Google Epoxy Paints and you'll find that almost all of them are now solvent free (note that our CM 15 summer time barrier coat epoxy does contain solvents). Usually solvents in epoxy paints is another indicator of an old, outdated, product being retired to the less informed "boat owner" market. Water Gard 300 is actually a higher performance CYCLO-ALIPHATIC EPOXY ADDUCT that can even be applied underwater! This is a step up in performance and quality for other epoxy paints (if they offered a cyclo-aliphatic epoxy adduct as a barrier coat you would certainly know it! Bilge Coating case study with Water Gard 300 too! Call us at: 603-435-7199 to talk about your barrier coat options (like, do you need ESP 155 epoxy primer? --- Water Gard 300 and ESP 155 are included in our TOP SELLING PRODUCTS catalog.

Hi Paul Subject: Great barrier coat success!

Date: Sun, 3 Feb 2002 10:58:06 -0500 |

Buy these products online or call 603 435 7199:

(find and buy everything we sell here)

|

Best way to make on-line Purchases PAYPAL (tm) keeps your credit card info off internet web sites visit the PAYPAL site to sign up now |

Customer feedback:

Dec 2008 from Doug: "The following is my opinion of a good company. My

affiliation is as a DIY end user. No recompense, no funny business: I've been

refurbishing our 1973 ketch and have done some epoxy work in that process. I've

never worked with epoxy before this. I talked to several local glass workers and

researched on line to learn a bit about epoxy. I searched for different vendors

and their prices. I settled on a place in New Hampshire called Progressive Epoxy

Polymers. (https://www.epoxyproducts.com)

My first thought was, what a mess of a website. I found it very confusing. Since I first came upon it, there have

been improvements made to make it more "user friendly". Aside from that, the site is most informative

to this beginning DIY's. I was won over by the explanations, descriptions of chemistries,

MSDS's , suggested usages,

and personal responsiveness of the owner and his wife. I did a calculation of prices per ounce, approximating the

match of the different brand's products. I realize that there is no way I can say I'm comparing the same chemistry

of different brands. Nevertheless, Progressive Epoxy prices remain the best I have found.

Progressive Epoxy Polymers is my epoxy source, I recommend them."

"Boats, boats and more boats.... After 17 years there is still no reason to buy from anyone else, great product, and great prices and the boats are still looking good." J.F.- 2-2-17

Subject: Barrier Coat Application

Date: Fri, 12 Mar 2004 09:41:16 -0500

Hi there,

I came across your web site as I was researching barrier coating the bottom of my new boat... I expect I should

apply a barrier coat... Using your formula (L x Beam x 0.85) I have about 166 square ft of below the waterline

surface area. Can you recommend an epoxy, brushes, rollers, thinners etc? I would need to do the job?

Hi Jeff

I think I would purchase a 3 gal kit of our white or blue Water gard 300. one coat is fine, but you will have a

lot left over, so might put a stripe coat on leading edge of keel, rudder, etc. then one coat over everything (thus

giving two coats on the wear areas). Also consider for the bilge, battery box, chain locker, etc. Another common

practice is to alternate coating colors (i.e. blue against a white fiberglass hull, white epoxy on top of blue

epoxy, etc. so that you can tell how deep scratches, chips or sanding results have progressed by the 'color coating').

Use our short nap epoxy roller or a paint pad (everyone likes the Rubbermade brand of paint pads sold a Walmart)

- bit more control with the paint pad. For clean-up or thinning (if going on too goopy due to low air or surface

temp) use MEK or xylene. If you use a 'regular' paint roller, the sticky epoxy sometimes pulls the lint out of

a new roller, leaving a fuzzy surface on your hull.

Generally you don't 'officially' need to sand before the bottom paint if applied within a few days (epoxies continue

to cure for about a week) but I like to suggest 'scratching up' the surface with coarse sandpaper any - say 30

minutes per side - to break up the glossy, slick surface of these epoxies.

We sometimes suggest a primer under the barrier coat, generally if the fiberglass is old, very dusty, etc. The

barrier coat epoxies are solvent free, so all bonding is a surface thing only. If the surface is less than 100%,

their could be bond problems. Using our CM 15, solvent based epoxy (20% solvent - very long pot life) will help

the bond because the CM 15 will, being thin and containing solvents, penetrate/seal the surface to some degree

and provide an ideal fresh epoxy surface for the epoxy barrier coat to bond with. Note that you could use several

coats of the CM 15 as your barrier coat too (it's thin, so probably 3, maybe 4 coats). Being thin, it will probably

go on with a regular roller instead of an epoxy roller. The CM 15 color is ivory. It has a very long potlife and

is probably the epoxy to use in temps over 85 or so degrees F.

Paul (4/2014):

Over the course of the last three days, I applied the black and then the ivory CM-15 epoxy paint to my fiberglass sailboat. It applied beautifully. The temperature ranged from 70 - 75 degrees and the humidity was in the 40-50% range most of the time. The last coat went on last evening about 6:30 pm with humidity creeping up a bit, due to an impending rain storm. Sanding at 24 hours was almost o.k.....not very much clogging, but some. I waited until 36 hours and it sands without any clogging.

DETAILS: 23' Sonar sailboat; best I could measure, about 140 sf to paint.

Mixed 1/2 of each gallon kit plus some solvent (2 oz) for each coat. Two coats of black, followed by two coats of ivory...all coats applied within 8-12 hours of each other.

Applied using your 9" close nap roller covers. Each coat took about 45 minutes to apply. Mixed......applied paint. No pot life issues and each half batch covered well with about 1/2 cup remaining after coverage. The last coat of ivory, I tried to apply more heavily and used all the paint, just as I finished.

The surface is why I would call a mild orange peel texture...not glass smooth. As soon as I can sand, I intend to use a longboard with 120 grit to knock the high points down.

Thanks for a great product. Mark -from MO

Thanks Mike D.

Joe wrote: Hi Paul: I used your blister repair kit with ease and both the penetrating

resin and the filler worked very much to specs. I was a bit unprepared for how thick (100% solids...) the

Water Gard 300 barrier epoxy paint is but still tried to use a 7" paint pad to spread it. The temperature ranged from

about 60º when I started at 8:00 to 74º when I finished around 2:00 pm. and the pad worked well at first

but it started to disintegrate after just a few strokes (vendor

comment: pad was a foamed backed one from Home Depot. Users report the Rubbermaid paint pads from Walmart work

well) , so I switched to one of your phenolic rollers. I had the (wrong) feeling that I wasn't putting on a thick

enough coat so I think I overloaded it a bit and while the horizontal (or almost) surfaces levelled off well, the

more vertical surfaces at the bow "cadscaded " (run) a little. When finished I had applied 16 qts. to

a theoretical 489 sq.ft. for an average 13 mils coat, well within the norm. Since I did it all by myself (dumb!),

I was so tired that did not notice the runs until the following day when the stuff was rock hard... Overall my

comments are that your products do exactly if not more than you say and I will strongly recommend them to other

sailors with the tip that rolling this stuff takes muscles and is easier if you borrow some! As to pot life I mixed about 3 pints at a time and applied

it in about 20 minutes with no problem. I kept refilling the roller tray also with no problem for about three hours

and then I had to throw one away because it got very thick even though I never got to the 40-45 minutes pot life

for the 70º range for each batch.

Dec 2008 from Doug: "The following is my opinion of a good company. My

affiliation is as a DIY end user. No recompense, no funny business: I've been

refurbishing our 1973 ketch and have done some epoxy work in that process. I've

never worked with epoxy before this. I talked to several local glass workers and

researched on line to learn a bit about epoxy. I searched for different vendors

and their prices. I settled on a place in New Hampshire called Progressive Epoxy

Polymers. (https://www.epoxyproducts.com)

Hi Paul

I think we have some converts.. We barrier coated the bottom of my boat

and the guys loved your water gard epoxy.They could not believe how easy it went

on and how fast it built up.. they also mentioned they liked the colors

blue and white.. They commented on how nice it was to have contrasting

colors to see where they left off from coat to coat... I think u will

start getting orders out of Daytona Beach very soon... i have been

using your epoxy myself and find it is very easy to work with... I'm

glad i took the chance on you. Your epoxy does everything you said it

would..

Subject: Great barrier coat success!

Date: Sun, 3 Feb 2002 10:58:06 -0500

Just a quick note to let you know about the great results I got from the Water

Gard epoxy. I just got

back in the water with my Sirius 28 "Eleuthera" and I'm extremely pleased with the performance

and ease of application. Thanks again for a great product. I highly recommend it as the premiere

barrier coat!

Captain D.R.V.

I just finished coating my 1983 41' Chris Craft and wanted to give you some feedback... I had the gelcoat planed

off not as much because of blisters (Only about 45 in almost 500 sq.ft.) but because the hull had 1/4 - 1/3 inch

of old, rotten antifouling and because parasites had eaten away the gelcoat at the waterline.

Once again, thanks for your good products... and advice!

Regards

Joe - Calistoga, CA

Marine Related Links:

|

COPPER-AND-EPOXY (low v epoxy) BOTTOM COATING SYSTEM --- CUSTOMER VIDEO

Can actually apply underwater in small touch up spots |

|

The Marine Epoxy Everything Guide Everything from user reviews, repair examples, pricing issues and vendor evaluation tips

Basic No Blush Marine Epoxy Product Page Marine Epoxy Catalog page (multiple epoxies) Basic No Blush Marine Epoxy User Reviews / Feedback How To Evaluating Marine Epoxy brands and Vendors Marine Epoxy prices - what it really costs! Marine Epoxy amine blush - what is epoxy Blush? Boat repair examples using Marine Epoxy Dinghy Marine Epoxy boat repair case study Progressive Epoxy Polymer's marine web site |

EMERGENCY YACHT UNDERWATER REPAIRA Case Study Using Progressive Epoxy Polymer's Underwater Epoxy - WET DRY 700 Underwater Epoxy and Corro Coat FC2100A (BUY NOW) read how our epoxies and customer service saved the day over a decade ago (2003). Read more (click here). Those products and service still available to you - call 603 435 7199 anytime and ask for Paul Oman. Underwater epoxy for Emergency hull repair - sinking yacht Case Study - now in book form at Amazon |

Available at Barnes and Noble and Amazon

|

|

BOAT BUILDING SUPPLIES AND INFO |

|

Non Blushing Marine Epoxy |

Marine Epoxies (find in

catalog) |

|

Epoxy Fillers / Thickeners |

Fiberglass Cloth |

|

"Stitch

and Glue" building |

Underwater Epoxy Repairs |

|

Varnish Info |

Varnish (find in catalog) |

|

Dinghy Repair |

Massive Boat Links Site |

| Email Us |

Call 603-435-7199 help/orders |

|

Basic No Blush marine epoxy has a long list of private and professional boat builders. Most recently (2016 -2017) The Drummond Island Tall Ship Company built the 72 foot schooner Huron Jewel using Basic No Blush epoxy. (CLICK HERE) Over 160 gallons of epoxy were used - switching from the standard curing agent to the winter and summer curing agents as the seasons changed. Other professional builders include a Drift Boat company, a boat building school, and it was used to construct one of the boats in a 'row across the Atlantic' competition several years ago. Read about the professional restoration of a Thistle Class sailboat with our epoxies. Some of our other epoxies can be applied underwater have been used to rebuild a 100 year old wooden marine railway in 12 feet of water and repair and raise a sunken yacht at a Pacific Island Atoll. Read all about it in the book "Escape From Hermit Island" available at Amazon.com. From Stitch and Glue kayaks to 72 ft schooners to emergency underwater repairs - you can trust the epoxies from Progressive Epoxy Polymers, Inc. - a Better Business Bureau supporter/member. - Company VIDEO - 603-435-7199 |

"

|

WE'RE THE BEST SOURCE FOR ALL BOATING RELATED EPOXIES AND COATING! HERE'S WHY: No matter if your boat repair/building project is sitting in a 39 degree barn or sunk in 10 feet of water in the local harbor, our epoxies can save your day. We have Kevlar (tm) reinforced epoxies, marine non-blushing epoxies with bubble breaker additives (no one else has that!), two part polys in white or clear, and old fashion spar varnish. The clear has massive amounts of UV blockers. Need an epoxy barrier coat or an epoxy sealer/primer for that old weathered fiberglass hull? Does you hull have blisters? Need a thickened epoxy or DIY epoxy thickeners? Does the pontoon boat leak? Need to repair a spongy, rotting deck core? We can do all of that and also save your sinking or sunk boat AND help you build that stitch and glue kayak or 72 foot schooner (they used 200 gallons of our epoxy!). PROGRESSIVE EPOXY POLYMERS INC. (marine catalog) or just call us 603 - 435 -7199 - available nights and weekends. Email anytime. - TOP FAVORITE EPOXIES --- WEB BOAT REPAIR LINKS --- BOAT EYE CANDY! |

|

Buy With Confidence |

|

|

BBB Certified Approved vendor

|

Always find/confirm Better Bus. Bureau accreditation when buying online. If they have it, they would show it! |

|

member (Paul Oman MS MBA) |

NACE (Nat Assoc Corrosion Engineers) |

|

member (Paul Oman MS MBA) |

SSPC (Soc of Protective Coatings) |

|

Like Us On |

|

|

Like Us On |

|

|

Don't be fooled by slick and flashy websites designed by marketing firms and web designers |

|

|

QUESTIONS? READY TO ORDER? |

EMAIL OR CALL 603 435 7199 - ORDER ONLINE |

Inside Our Marine Catalog:

Section One TWO PART MARINE EPOXIES- CLEAR EPOXIES

basic no blush epoxy, premium no blush epoxy, esp 155 epoxy, low v epoxy

Section Two FILLERS THICKENERS ADDITIVES

fumed silica; microsphere/balloons; poly fibers; graphite, wood flour; EZ thick; rock flour

Section Three THICKENED EPOXIES - EPOXY PUTTIES, ETC.

wet/dry 700; splash zone; epoxy cream; splash zone a-788

Section Four TWO PART EPOXY PAINTS (barrier coats)

corro coat FC 2100; water gard 300; CM 15; liqua tile 11 72 potable water; rough coat; water prime

Section Five URETHANES AND NON-EPOXY COATINGS Aluthane (aluminum coating); LPU Marine; india spar varnish; acrylic poly uv plus, polyester poly

Section Six NON-SKID DECK COATINGS

walnut shell,; s15

Section Seven MARINE REPAIR PRODUCTS

pipe wrap; fiberglass tape (cloth); Capt. Tolley's Creeping Crack Cure

Section Eight MISC. MARINE PRODUCTS

short nap rollers; TA 661 (solvent free epoxy clean-up); 1 inch foam brushes; 2 inch bristle brushes; tongue depressors

Questions? / Phone order? / EMAIL / CALL 603-435-7199 EST / BUY ONLINE

GOOGLE SITE SEARCH - Click here Epoxy specific site search

Click here - YouTube video. Learn about Progressive Epoxy Polymers Inc.

Click here - Dozens of boat repair info links across the internet. - (everything is here!)

THREE MUST READ WEB PAGES

MPRICES - 2 part marine epoxy pricing issues - CLICK HERE -

MEPOXIES - comparing 2 part clear marine epoxies - CLICK HERE - (you are here already!)

EVAL4U - how to evaluate your marine/non marine epoxy vendor - CLICK HERE -

(QUESTIONS, ORDERS, ETC. WE CHECK EMAILS MULTIPLE TIMES EACH DAY AND ON WEEKENDS/HOLIDAYS)

Need More?

Ask the EPOXY GURU

Ask Professor E.Poxy

Click here - Company YouTube video (who we are!).

|

Let's stay connected. It's a win-win situation. Receive our online NEWSLETTER by emailing us your name and email address. |

** Quick EMAIL / ph 603.435.7199 EST / Google SITE SEARCH / Buy On-line TWO STORES / Goto Contact PAGE / Web Product CATALOG / Progressive Epoxy HOMEPAGE / View our VIDEO / Navigation Bar REPLACEMENT / Data and MSDS PRODUCT INFO / Epoxy Guru HELP SITE / Top Selling Products - FAVORITES * *

NOTICE: Legal notices, Terms of Service, warranty information, disclaimers, health warnings, etc. are required reading before using web site, ordering and/or using Products. Any such use and/or ordering, online or by telephone, shall constitute acceptance and knowledge of all such terms. CLICK HERE to access these terms. Please note: Whenever you purchase from this web site, and with each new purchase, you are granting us full and complete permission to add you to our email newsletter list at our option. RETURNS: call or email for authorization to return. Returns are subject to a 25% restock fee. Customer pays return shipping and must comply with federal DOT shipping requirement/labeling for hazmat epoxies under penalty of fines and legal action.

Great Marine Epoxy Barrier Coat Rip-Off -

Underwater Epoxy

Fiberglass boat - marine epoxy paint - barrier coat INFO page