PROGRESSIVE EPOXY POLYMERS, INC.

CALL 603-435-7199 (or email).We are the only technology based coating/epoxy/resin company that actively encourages your phone calls, not just during our East Coast work hours but also after/before hours, evening, weekends and even holidays. We're available when you are. We form a personal relationship with our customers and freely share technical information, how to-advice, product information and tips-and-tricks. Speak with a non-salesman technical professional with over 25 years of experience in the resin/coating/epoxy industry (no newbie staffer on the phone lines!). Floors, tables, boats, leaks, rot repair. We handle it all! We are an 'always available,' one-on-one, technical/scientific, coating company (watch our video). We are NOT one of those fluffy/slick mass sales firms the dominate the internet selling cheap third party (made in China???), low end epoxies and coatings with no real knowledge of what they are selling and quotas to sell to as many people as possible. 603-435-7199 (east coast time).

PRIMARY STORE LINK --- TOP SELLING PRODUCTS --- EPOXY GURU HELP SITE --- EPOXY DATA SHEETS

EPOXY FLOOR PAINT

It would seem that painting a concrete slab or wall should be a simple task

with minimal problems. This is often so, but things change when the concrete is on damp ground, below the water

table, or in direct contact with moisture.

Vapor Barrier - moisture issues in epoxy garage floors

moisture transmission and vapor barriers for epoxy floors

Your Host and Tour Guide:

Paul Oman, MS, MBA - Progressive Epoxy Polymers, Inc. (floor epoxies, marine epoxies, underwater epoxies, repair epoxies)

Member: NACE (National Assoc. of Corrosion Engineers), SSPC (Soc. of Protective Coatings)

"Professionals helping Professionals"

PROGRESSIVE EPOXY POLYMERS, INC.

|

PAGE AND SITE NAVIGATION |

|||||||||||||||||

Epoxy Floor Links Page ====> This 'Linked To' Epoxy Floor Sub-Page

No Sales Tax applied. Save Money, you're shopping in Tax Free New Hampshire

MEMBER: Internet Epoxy Confederation (IEC - CLICK HERE TO VISIT) -- "Where Professionalism Still Matters"

We've been selling epoxy - marine epoxy (boat building - wood / fiberglass repair) industrial coatings - garage paint - underwater epoxies - thick putties - tabletop resins and supplies since the early 1990's |

Epoxy Floor Section in our online catalog - CLICK HERE

It would seem that painting a concrete slab or wall should be a simple task

with minimal problems. This is often so, but things change when the concrete is on damp ground, below the water

table, or in direct contact with moisture.

THE PROBLEM

Concrete is not the hard, dense, impermeable mass we tend to imagine it to be. It's a mineral/salt rich, porous

material full of tiny channels and voids. These pathways are just right for the migration of fluids and vapors.

Migration is due to simple physics - forces working to achieve temperature, humidity, concentration, or pressure

(hydrostatic) equilibrium.

But there is more to it than simple equilibrium induced fluid migration. Dissolved metal salts in the migrating

water can form relatively large calcium/potassium silicates (in a typical alkali-silica reaction) upon reaching

the concrete surface. This ‘swelling' can result in pressure build-ups of well over 1000 pounds. That's a lot of

pressure for any coating bond to resist.

Added to this situation is one more wrinkle. Nearly all coatings lose bond strength, or simply will not adhere

at all, when applied to a damp, wet, or saturated surface. How dry is your concrete surface? Chances are it contains

more moisture than the coating manufacturer would recommend for optimum adhesion.

We really appreciate you visiting PROGRESSIVE EPOXY POLYMERS, INC. and our web site: EPOXYPRODUCTS.COM. Take advantage of the CONTACT links on this page to ask questions about our products and/or your projects. You can stay in touch with us via our NEWSLETTER (link on our contact page) which is emailed every 6-8 weeks.

|

Epoxy Only Web Google Search |

|

|

#1) Google Everything Epoxy Searches #2) Google Marine Epoxies Searches

#3)Google

Floor Epoxy Searches |

|

View our Progressive Epoxy Products, Inc. |

This current page is all about:

|

|

WOW! 35% - 40% of all daily online or telephone orders are from existing customers. That's an amazing 'REPEAT CUSTOMER" number. |

|

603 - 435 - 7199 ANYTIME 24/7 FOR HELP OR ORDERS |

|

|

|

|

VAPOR BARRIERS

The pre-construction solution is to use a vapor barrier under the concrete. This vapor barrier is nothing more

than a heavy plastic sheet. Unfortunately contractors or owners often discover that no vapor barrier was used or

that the vapor barrier has probably been torn or damaged, possibly when the concrete was poured. Older buildings

and garages often do not have a vapor barrier.

Do You Have A Vapor Barrier? Sometimes it's easy to tell if you're lacking a much needed vapor barrier. There could

be water (smelly water) under the carpet or wood floor sitting directly on the concrete. If the surface is painted,

there might be water filled blisters in the paint. Pop them open and they may literally squirt water several feet

into the air. If the concrete is not covered, it could be covered with tiny crystals, the result of mineral salts

being left behind by the migrating moisture.

One way to test the exposed concrete for moisture migration is to tape a sheet of plastic (several square feet

in area) to the floor and see if water condenses under the plastic. A lack of condensed water doesn't rule out

a possible problem. Moisture migration might occur only after rainstorms, spring thaws, or other occasional events.

TREATING A VAPOR BARRIERLESS FLOOR

How do you fix a floor with a vapor transmission problem? There are lots of partial solutions, but no ‘sure thing'

short of pouring new concrete over a new vapor barrier.

A ‘Breathable' system is one common solution. This lets the moisture pass through. Depending upon your requirements,

especially if you're just looking for an attractive surface, this may be all you need. There are a growing number

of porous rugs, paints, and other surfaces on the market.

Next are special sealers (such

as Bio Vee Seal - http://www.epoxyproducts.com/vee4u.html) that soak into

the concrete and form crystals within the voids and channels inside the surface of the concrete. This reduces permeability

and porosity of the concrete, generally restricting the flow of fluids, but not vapors, through the matrix. If

the concrete is exposed, this treatment is easy and quick and just might ‘densify' the concrete enough to solve,

or greatly reduce, the problem. A product like this might also assist in the bonding of regular paint or epoxy

which would normally fail, by lessening the amount of mineral salts, etc. the can migrate to the concrete - coating

interface. When used in this (untested) fashion, the Bio Vee Seal would become a primer of sorts.

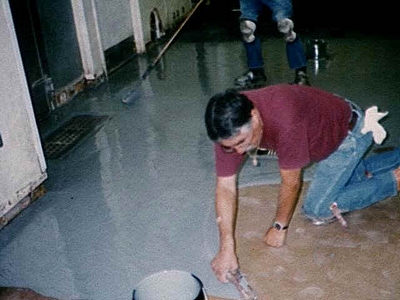

Finally, there is at least one line of rollable epoxies and floor epoxies that can bond to wet or damp surfaces

(http://www.epoxyproducts.com) so well that they can resist the pressures (over 1000 pounds) that can build up

on the surface of the concrete at the coating interface. This approach offers a simple, roll on, impermeable barrier

on the inside surface of the concrete. By sealing the concrete surface, moisture, concentration, and pressure equilibriums

would be reached inside the concrete which would stop the flow or movement of moisture, although not its presence.

Bond adhesion, however, is influenced by more than just moisture levels. A good, strong bond requires careful surface

preparation. The surface must be clean, dust free, solid (not chalking or deteriorating), and have a good profile

(microscopic peaks and valleys) to permit maximum surface contact. The presence of pre-existing coatings, sealers

or grease/oil spills could preclude a good bond also.

CONCLUSION

Moisture and salts can and do migrate through concrete slabs as they seek equilibrium with the environment above

the concrete. The resulting pressures and condensing water vapor can ruin painted floors, rugs, wooden flooring

and almost anything placed over the concrete. After-the-fact solutions include using a breathable surface coating,

reducing the porosity and permeability of the concrete and/or using special epoxies that can bond sufficiently

well to moisture rich concrete so as to successfully resist the forces that can develop.

####

Epoxy Only Web Google Search

#1) Google

Everything Epoxy Searches

#2) Google

Marine Epoxies Searches

#3)Google

Floor Epoxy Searches View

our Progressive Epoxy Products, Inc.

|

ONLINE PRODUCT CATALOGS PROGRESSIVE EPOXY POLYMERS, Inc |

|

|

ONLINE STORE Purchase Here ------ or CALL 603 435 7199 ------ HOME PAGE |

|

|

Marine Catalog |

|

* home

page of marine catalog section (blue background)

|

|

| Section One MARINE - CLEAR EPOXIES Section Two FILLERS THICKENERS ADDITIVES Section Three THICKENED EPOXIES - EPOXY PUTTIES, ETC. Section Four EPOXY PAINTS (barrier coats) Section Five URETHANES AND NON-EPOXY COATINGS Section Six NON-SKID DECK COATINGS Section Seven MARINE REPAIR PRODUCTS Section Eight MISC. MARINE PRODUCTS |

|

|

MASSIVE BOAT HOW TO - ISSUES - HELP WEB LINK SITE |

|

|

Residential / Commercial / DIY Catalog |

|

* home

page of residential/commercial catalog section (brown background)

|

|

|

Section A EPOXY PAINTS Section B FLOOR EPOXIES (regular and non-skid products), SEALERS, ACCESSORIES Section C THICKENED EPOXIES - EPOXY PUTTIES, ETC. Section D CLEAR EPOXIES Section E NON-EPOXY PAINTS COATINGS SEALERS Section F MIX-IN ADDITIVES Section G OTHER PRODUCTS Section H SURFACE PREPARATION PRODUCTS Section I MISC. ACCESSORIES |

|

|

WEB EPOXY FLOOR ISSUES LINKS SITE --- WEB EPOXY REPAIR LINKS SITE |

|

|

top selling favorite products for your every need Buy Talk Chat Support EMAIL or 603 435 7199 American manufactured, distributed, and sold epoxies and coatings. Your business helps small American Family Businesses - Thank You! |

|

|

|

||

|

site master |

protagonist |

ground zero |

Vapor Barrier - moisture issues in epoxy garage floors

moisture transmission and vapor barriers for epoxy floors