PROGRESSIVE EPOXY POLYMERS, INC.

**

EMAIL / ph 603.435.7199 EST / BUY ONLINE **

This page, while still valid, has received a major upgrade. This page is a

subpage of the massive www.epoxyproducts.com web site.

Because of high demand, the updated version now has its own

web domain / web site - www.underwaterpoolepoxy.com

- Both this page, and the new domain and page are both

online and valid (better for the search engines LOL).

We have other epoxies that can be applied underwater

- see www.underwaterepoxy.com

Need more info? support - questions - buying links?

- Goto our Contact Page.

FYI - the product you are probably interested in is called WATER GARD 300

You can purchase it online at www.epoxyusa.com Most customers only need

the 1.5 quart kit (light blue or white) as it is only for small spot repairs

in residential swimming pools.

(WE ALSO SELL EPOXIES TO RESEAL YOUR PEBBLE DECK AROUND YOUR POOL)

Nothing but Quality Underwater Swimming Pool Repair Epoxies at Good Prices, Great Customer Service, and

Lots and Lots of Helpful Information

and NO SALES TAX - You are shopping in TAX FREE New Hampshire

Nothing but Quality Products at Good Prices, Great Customer Service, and Lots and Lots of Helpful Information

and NO SALES TAX - You are shopping in TAX FREE New Hampshire

Your Host and Tour Guide:

Paul Oman, MS, MBA - Progressive Epoxy Polymers, Inc. (floor epoxies, marine epoxies, underwater epoxies, repair epoxies)

Member: NACE (National Assoc. of Corrosion Engineers), SSPC (Soc. of Protective Coatings)

Board member: Friends of the Suncook River - 501(c)(3) non profit ----- Founder: Friday Night Paddlers .

"Professionals helping Professionals"

Hey Paul, Just wanted to drop you a line. Just wanted to thank you again for your Water Gard 300 under water epoxy paint. As we have discussed in the past, we have a Commercial Steel pool, and no matter how well we prep it for paint each year, we always end up with a few rust spots part way through the season. Once again your Water Gard 300 came to the rescue to touch up some particularly ugly rust spots this year.

Thanks Again! Howard - Dxx Swim Club

"Thanks for all your advice, tips & moral support concerning my project. It turned out beautiful. Quality people backing a quality product is the only way to go!" Joe

We are the only technology based coating/epoxy/resin company that actively encourages your phone calls, not just during our East Coast work hours but also after/before hours, evening, weekends and even holidays. We're available when you are. We form a personal relationship with our customers and freely share technical information, how to-advice, product information and tips-and-tricks. Speak with a non-salesman technical professional with over 25 years of experience in the resin/coating/epoxy industry (no newbie staffer on the phone lines!). Floors, tables, boats, leaks, rot repair. We handle it all! We are an 'always available,' one-on-one, technical/scientific, coating company (watch our video). We are NOT one of those fluffy/slick mass sales firms the dominate the internet selling cheap third party (made in China???), low end epoxies and coatings with no real knowledge of what they are selling and quotas to sell to as many people as possible. 603-435-7199 (east coast time).

Divers applying Underwater Epoxy for Commercial Aquarium Repair

|

In A Nutshell....

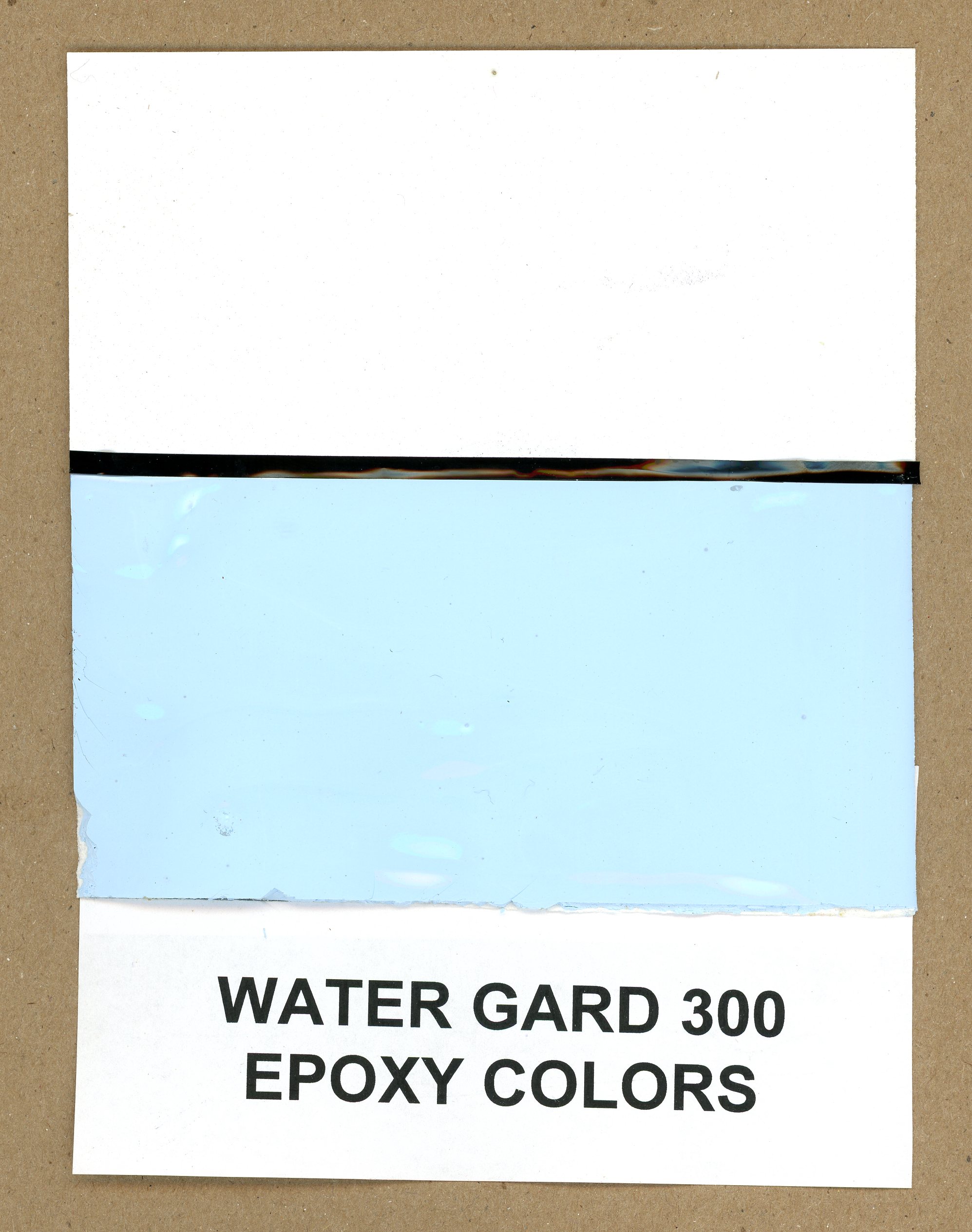

You can apply the very thick

Water Gard 300 epoxy paint underwater to fix small leaks or chips in your

swimming pool (or spa or aquarium or fountain). Colors are white and light

blue.

Our Wet Dry 700 epoxy is a kelvar (tm) reinforced epoxy putty that can

be used underwater as well for 'serious' repairs. Color of the Wet Dry

700 is off white but it will turn yellow quickly. They work great on non

underwater repairs as well.

Order Water Gard 300 or Wet Dry 700

at

www.epoxyusa.com

or call 603-435-7199 to order or for

questions.

WATER GARD 300 in 1.5 quart kits and 3 quart kits (light blue or white) WET DRY in 1 quart kits and 1 gal kits (off white quickly turns to a yellow color - can topcoat with the blue or white WATER GARD 300)

"Paul -- I used your Wet Dry 700 epoxy paste several years ago (from you) to repair cracks in the floor of my gunite pool. Been holding up well. Now I need to attach some tile. Very easy to use product." -- John (5/2019) Top 7 List Of Reasons for Using Our Underwater Repair Epoxies: 1) Special epoxies that will bond underwater (white/blue Water Gard 300) 2) Epoxy (Wed Dry 700 epoxy putty) contains Kevlar (tm) fibers for gap filling and serious repairs 3) 24/7 email support 4) Honest and complete info (pro and con) on this site. You get the FULL story. 5) Sold by an epoxy coating company and not a sales/marketing firm 6) Made in the USA 7) We appreciate your interest and thank you sincerely for your business!

|

Repair Swimming Pool Chips - Stains and Cracks

|

Water Gard 300 (tm) Epoxy apply underwater touch- up epoxy |

|

|

|

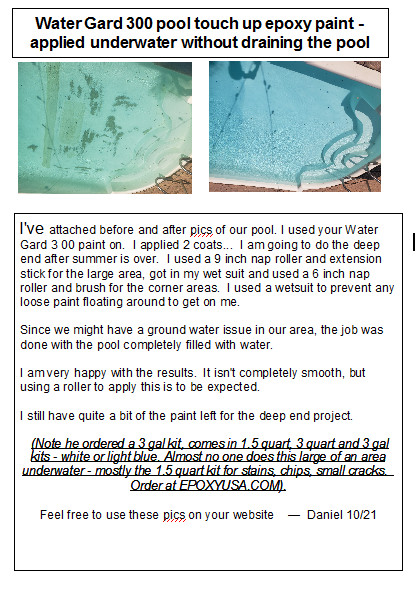

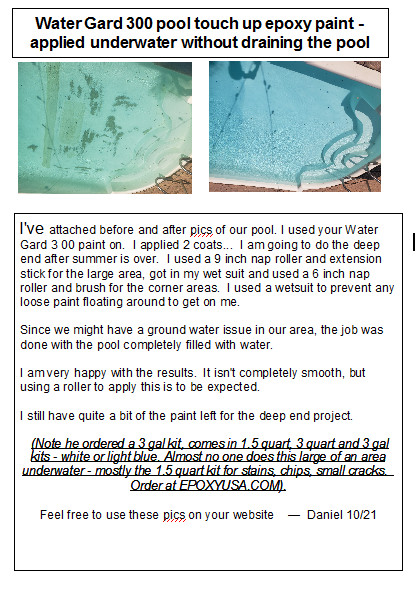

ABOVE - before applying Water Gard 300 underwater |

|

|

|

ABOVE - after applying Water Gard 300 epoxy underwater |

|

"Thanks Paul - my 24 year old fiberglass pool looks new" --- Helen 5/18 |

|

order 1.5 quart light blue or white -- product web page -- call 603 435 7199 |

ONLY SHIPPED WITHIN THE LOWER 48 STATES / USA

READY TO BUY?

visit our contact page for where to buy Water Gard 300 from our online store - or to call for questions - support - phone and business hours

Introduction:

We do not carry swimming pool paint / epoxy, but we do have products that are used in pool repair and preparation.

We sell a lot of the Water Gard 300 "apply underwater" epoxy paint in

white or light blue (1.5 quart units). For more serious pool repairs in pools

that are drained of water, give us a call 603 - 435 - 7199.

Cracks: fixing cracks underwater

Note repair products may stop or plug the crack but will not address the cause of the problem (settling, ground movement, etc.) so the crack may re-open or new cracks may appear.

Fixing large cracks in dry or water filled pools: use our WET DRY 700 (about 30 - 60 minute working time - color off white).

--- Quick Purchase this product at our simplified www.epoxyUSA.com site ---

Chips: Touch-up paint without draining pool:

Use our Water Guard 300 (1.5 quart kit) epoxy paint - light blue or white color available.

ONLY SHIPPED WITHIN THE LOWER 48 STATES / USA

Re-attaching - reattaching pool tiles:

(underwater or in dry conditions) use Wet Dry 700 underwater epoxy putty

This product is a Progressive Epoxy Polymers, Inc. best selling, favorite product. Visit our FAVORITES - 7 EPOXIES THAT WILL FIX ANYTHING web page at: epoxyproducts.com/favorites4u.html View other popular one-of-a-kind products.

Warning -- where it might not work:

When WATER GARD 300 (tm) epoxy

will not stick underwater

– common causes —

Progressive Epoxy Polymers, Inc.

Paul Oman 8/2020

Water Gard 300 (tm) is a solvent free epoxy that can be applied underwater. Most users purchase it for minor swimming pool touch up without draining the water.

That said, sometimes it will not to stick to surfaces underwater. It is not the epoxy (test it in a bucket of water on a submerged stone, piece of wood, etc. to confirm that it can be applied underwater and the issue is something unique to your environment, and not the epoxy).

Here are some reasons why the adhesion fails:

** Epoxies stick underwater by tiny electrical charges. Existing electrical charges in sea ports, harbors and commercial ships, known or un-known, will keep the epoxy from bonding. Generally this is in a conductive salt water environment with two different metals nearby. An electrical field can also be created with electrical equipment attached to shore power. Cathodes attached to the bottom of some boats will also create an electrical field (that is how they work!).

** Epoxies do not stick to vinyl pool liners and other plastic surfaces (polyethylene, polypropylene for example).

** Many commercial cement pools have special additives in the cement to drive out the air in the concrete during installation (a silicon?) which makes the concrete more dense and more likely to pass density tests for commercial poured concrete. Perhaps half of commercial pools have this issue and the epoxies will not bond to the cement. Only very rarely does this situation occur in residential pools.

** The cement or gunite in the underwater surfaces of the pool is so weakened from years and years of pool chemicals that while the epoxy will stick to it, the weight of the epoxy coating will pull off the pool side, usually with a thin failed layer of pool gunite or cement grains attached to the back side of the epoxy.

** Years and years of suntan oil or sun screen can collect on swimming pool steps and result in a slick surface that will keep the epoxy from bonding.

==============

Nearly all the time on non-commercial pools the Water Gard 300 epoxy paint is successfully applied to small areas of residential pools successfully - thus saving having to drain (and refill) the pool to hide a stain, fill in a chip, etc.

In theory an entire pool can be painted underwater with Water Gard 300 epoxy, but in the last 20 years this has never been done, although several customers have wanted to do it (too much effort, too many other issues). The product is best used for spot re-coating and repair of areas a few square feet in size.

Customers have been able to slightly shift the white or light blue colors by adding non water based, non powder pigments form craft stores or paint stores.

Note that in all the above cases, the problem is not with the epoxy but rather the environment it is being used in. Progressive Epoxy Polymers, Inc. has no obligation or responsibility for the above conditions that result in non-adhesion of Water Gard 300 epoxy underwater. Purchase at your own risk.

BUY ONLINE: epoxyusa.com

Customer feedback:

Hi Paul. This is Dave from San Angelo, Tx. As I told you before, the underwater applied epoxy worked great. I recommend you send your product info to all pool companies and pool supply retailers or if you can find out who has fiberglass pools and send them info if they ever need it. Thanks 6/16

"My story. We have a fiberglass pool that is 31 years old. I know they are not supposed to last that long. But this one is starting to have ‘surface’ cracks (and I think more than surface cracks). We have ordered the Water Gard 300 epoxy twice to fix them and it has worked GREAT. That is the best stuff EVER…

I can’t drain my pool, because I have a really high water table. (the pond in my back is ground water---). And I think the integrity of the Fiberglass is gone. My grandkids love the pool. We are just trying to keep it together for the rest of the season, then figure out what to do." --- Peggy G. 9/15

8/14 -- My name is T..R... and I live in Las Vegas, Nev. I have a beautiful custom pool and I noticed a small area on the side wall of my pool. I took a wire brush and tried to remove the dark colored spot. Unfortunately I rubbed too hard and made it worse, much worse.

I contacted 10 different pool companies and each of them informed me that I would need to drain the pool to repair the spot that was getting larger by the day. Draining a pool with 28,000 gallons during the summer is bad enough, but fixing the plaster that had been rubbed down to the Gunnite is very expensive. I needed a quick fix and there did not seem to be one! Well, I was wrong.

I discovered a man named Paul Oman at epoxyproducts.com on the internet when I searched for (plaster underwater repair) and to my amazement he told me about an epoxy that you mix in a ratio of 2 to 1 (Water Gard 300 - available in white or light blue).

Once last thing, Paul sent me the white at my request. I mixed a light blue paint from a hobby store and my pool looks great. This product is perfect and it is for real. Do yourself a favor and don’t listen to the pool guys, they want your business and that adds up to big bucks!

Thanks again Paul for helping me solve this problem. --- T..R..

"Hey Paul, Just wanted to drop you a line. Just wanted to thank you again for your Water Gard 300 under water epoxy paint. As we have discussed in the past, we have a Commercial Steel pool, and no matter how well we prep it for paint each year, we always end up with a few rust spots part way through the season. Once again your Water Gard 300 came to the rescue to touch up some particularly ugly rust spots this year. Thanks Again!" Howard - Dxx Swim Club

"Just wanted to let you know that the white water guard 300 I

purchased to repair my fiberglass swimming pool underwater

worked great!!! Just what I was looking for. The product covered

more area than I expected, but I may be ordering more!!! Did test

spots on shallow area and steps, and It looks like it did 31 years

ago. Going to tackle the deep area next. Tested using a brush and a

roller. The paint brush worked a little better for me. Thank You So

Much!! I will share with others!" ----- Helen from LA. "All I can say

is thank you....

Virginia -- Key West (7/17)

Paul,

"Just wanted to let you know that your Water Gard 300 pool touch up kit was a life saver for us this year. We painted our Swim Club pool this year, and the pool paint we used turned out to be super slippery. Opening day we had several people comment on how slippery the steps were leading into the shallow end of the pool. We were scrambling to figure out how we could fix that since the pool was now full of water, and then we remembered that we had bought a kit of your Water Gard 300. After we closed that night we mixed some of your epoxy with a little bit of sand and brushed it on the the steps.

It was like magic, the steps were no longer slippery, and the color nearly matched the pool paint. The next day, folks were none the wiser that the steps had been painted the night before, and the steps had just the right grip for safe entry into the pool.

We are now over a month into the season, and the paint has held up excellently. Last night we used it to touch up some rust spots (Our pool is actually Steel) that had bled through the pool paint.

We will definitely be using more of your product next year.

Very Best Regards,"

Howard (7/7/17)

(The entire pool is steel (never any issues or problems with metal pools) It is a 5 lane competition length pool. It was built in 1955. Steel was cheep and welders were even cheaper when the Korean finished up, so they built it out of steel. When the water is out you can still see the weld seems every 5 feet or so, even through the layers and layers of pool paint.

Unfortunately, the water gets under the paint or the paint layers peel off, and then we get rust spots showing through. Every year we have to scrape and repaint.)

|

|

Paul, I'm not the kind of person to give feedback on products or services but I must comment on the Water Gard 300 product. I purchased a home 4 years ago with a fiberglass pool and 2 years ago it started to significantly chip. Long story short, after significant analysis from multiple experts, it turns out that the pool had ruptured and was repaired. Unfortunately the repair person applied the fiberglass topcoat incorrectly and it is all coming off. Luckily the pool is structurally sound, just very ugly to look at. Estimates to fix it range from $8,000 to $25,000 and no one would guarantee that the entire pool would not collapse after draining the water which would require an entire replacement.

|

|

|

|

After a year

of searching, and countless attempts at other solutions, I came

across your product. This product is amazing! I still can't believe

it's even possible to apply a paint (sorry epoxy) underwater. I used

a 14 foot extension pole with a roller to apply the paint/epoxy. The

most time consuming part was mixing parts A and B together. I

purchased the 3 gallon size but since I was working alone I mixed

small batches since the pot life was short. For roughly $350 my pool

looks brand new! I can't thank you enough. I've attached some before

and after pictures.

Thanks again, David

|

|

Buy Water Gard 300 underwater epoxy paint here (CLICK HERE)

|

Links for UNDERWATER EPOXY Application of "Apply underwater" epoxy paint and putty for repair and as an adhesive. Underwater swimming pool epoxy paint and repairs - Wet surface painting. Yes, you can apply some special epoxy paint/putty coatings UNDERWATER

1) DIY application of underwater epoxy paint (photograph) ----- uwpaint.html 2) underwater repair epoxy saves sinking yacht ----- cs_boat.html 3) history of underwater paint putty epoxy ----- uwhistory.html 4) description / buy links to underwater epoxy paint putty adhesive ----- under4u.html 5) epoxy and non epoxies that can be used (not applied) underwater ----- immerse.html (this page)

Contact Page (phone or email us) Links to online storefront for buying UNDERWATER EPOXY Splash Zone A-788 -- Wet Dry 700 -- Corro Coat fc2100A -- Water Gard 300 |

!!! UNDERWATER EPOXY APPLICATION WARNING !!! |

| Many concrete / plaster industrial -

commercial pools (i.e. camps, aquariums, apt complexes, schools,

cities, institutions, etc.) have special additives in the

cement/plaster etc. that will prevent underwater epoxies from

adhering when attempting to apply underwater. Proceed with care.

There is no way to know without testing. Very few private homeowner

pools have this issue.

Saltwater pools or environments (harbors, inlets etc.) can generate electrically conductive environments which can also prevent underwater epoxies from bonding. see CATHODIC ISSUES with saltwater. |

Search the EPOXY-ONLY World Wide Web search engine

for your Epoxy Related Search term

CLICK HERE FOR EPOXY RELATED SEARCHES

(QUESTIONS, ORDERS, ETC. WE CHECK EMAILS MULTIPLE TIMES EACH DAY AND ON WEEKENDS/HOLIDAYS)

Need More?

Ask the EPOXY GURU

Ask Professor E.Poxy

Click here - Company YouTube video (who we are!).

| "Hi there! This e-mail has no question but I was just looking through your site and I wanted to say that it's great! I was just looking around the internet to read about the subject of epoxy and no other site I visited was as helpful as yours. You are very knowledgeable in that subject and I admire that. Great work and I wish you the best! " - Gabriella 10/15 |

|

You don't find endorsements like this on other sites! |

|

"Hi Paul, ---Thank you so much for all the info. Each time I spoke with you, I found you to be a very helpful, personable individual. You seemed genuinely interested in helping me get the right products and making sure that I know exactly the best way to apply it for optimum results. Sadly, in today’s business world, those are not common traits. It definitely was a pleasure to do business with you ( as cliche as that saying is.) I definitely will recommend to anyone who needs your products. Best wishes for continued success. Sincerely, Julie" (6/2019) |

\

|

Let's stay connected. It's a win-win situation. Receive our online NEWSLETTER by emailing us your name and email address. |

|

MARINE CATALOG |

HOME/DIY/COMMERCIAL CATALOG |

|

Section One

TWO PART MARINE EPOXIES- CLEAR EPOXIES |

Section A EPOXY PAINTS; NSP 120; water gard 300 ; CM 15; crack coat™ |

|

Section Two

FILLERS THICKENERS ADDITIVES fumed silica; microsphere/balloons; poly fibers; copper; graphite; Teflon (tm); wood flour; EZ thick; rock flour

|

Section B FLOOR EPOXIES (regular and non-skid products), SEALERS, ACCESSORIESwater bond (water based); solvent free industrial floor epoxy; bio vee seal; water based floor epoxy, floor epoxy with grit; walnut shell; ground white rubber grit |

|

Section Three

THICKENED EPOXIES - EPOXY PUTTIES, ETC. wet/dry 700; splash zone; quick fix 2300, QR 2400 rubber epoxy |

Section C THICKENED EPOXIES - EPOXY PUTTIES, ETC.wet/dry 700; splash zone A-788, quick fix 2300; QR 2400 (tm) rubber epoxy |

|

Section Four

TWO PART EPOXY PAINTS (barrier coats) corro coat FC 2100; water gard 300; CM 15; EZ Spray; epoxy primer; crack coat™ |

Section D CLEAR TWO PART EPOXIESlow V epoxy; basic no blush; ESP 155; Bio-Clear 810 |

|

Section Five URETHANES AND NON-EPOXY COATINGS Aluthane (aluminum coating); LPU Marine |

Section E NON-EPOXY PAINTS SEALERSAluthane moisture cured urethane; Acrylic Poly UV Plus and other 2 part polys ; Capt. Tolley's creeping crack sealer |

|

Section Six

NON-SKID DECK COATINGS walnut shell; ground white rubber

|

Section F MIX-IN ADDITIVESfumed silica; fiber fill; micro balloons/micro-spheres; graphite; Teflon (tm); copper powder; wood flour; EZ thick, rock flour |

|

Section Seven

MARINE REPAIR PRODUCTS pipe wrap; fiberglass tape (cloth); Capt. Tolley's Creeping Crack Cure |

|

|

Section Eight

MISC. MARINE PRODUCTS short nap rollers; TA 661 (solvent free epoxy clean-up); 1 inch foam brushes; 2 inch bristle brushes; tongue depressors |

|

|

|

|

|

Call (603-435-7199) or EMAIL with questions /phone orders etc. about what you're doing. We try to earn your business one phone call at a time! |

|

NOTICE: Legal notices, Terms of Service, warranty information, disclaimers, health warnings, etc. are required reading before using web site, ordering and/or using Products. Any such use and/or ordering, online or by telephone, shall constitute acceptance and knowledge of all such terms. CLICK HERE to access these terms. Please note: Whenever you purchase from this web site, and with each new purchase, you are granting us full and complete permission to add you to our email newsletter list at our option. RETURNS: call or email for authorization to return. Returns are subject to a 25% restock fee. Customer pays return shipping and must comply with federal DOT shipping requirement/labeling for hazmat epoxies under penalty of fines and legal action.

Progressive Epoxy Polymers, Inc.

603.435.7199

Pittsfield, NH 03263

Navigation Bar frame replacement CLICK HERE mobile friendly key site links